What Is Fmea: Definition And Stages

Di: Everly

Failure mode (FM) refers to the way in which something might break down. It includes potential errors that might occur, especially errors that could affect the customer.

Failure mode and effects analysis (FMEA) is defined as a proactive risk-assessment method used to identify and evaluate potential failure modes and their effects on a product or process. FMEA is widely used in

Guide: Failure Modes And Effect Analysis

DEFINITION ♦FMEA is a systematic analysis of potential failure modes aimed at preventing failures. It is intended to be a preventive action process carried out before implementing new or

Stages of FMEA in Total Quality Management – Download as a PDF or view online for free. Submit Search. Stages of FMEA in Total Quality Management . Nov 19, 2020 0 likes 486 views

FMEA stands for “ Failure Mode and Effects Analysis “. It is an analysis method used to rank potential failure modes of a product in advance, visualize high-risk items, and

FMEA, continually informing, shaping and optimising the final product. It is important to consider FMEA as an iterative technique that should be carried out at all stages of the design process.

- Guide: Failure Modes And Effect Analysis

- What is FMEA? A Guide to the Failure Mode and Effects Analysis

- What is FMEA? Failure Mode & Effects Analysis

FMEA defines the term “failure mode” to identify defects or errors, potential or actual, in a product design or process, with emphasis on those affecting the customer or end user. A “failure effect”

What are the Types of FMEAs? DFMEA, PFMEA, & FMECA

What is a PFMEA or Process FMEA? Process FMEAs are used to analyze and maintain process control objectives. Essentially, PFMEAs are performed on a process as

What is FMEA? Failure Mode and Effects Analysis, or FMEA, is a systematic method used to identify potential failure points within a product, process, or system, assess their impact, and

Wondering what Failure Mode and Effects Analysis (FMEA) is? It’s a systematic approach to addressing potential failures in processes, products, or systems. This blog explains its steps, benefits, and practical applications,

FMEA plays a pivotal role at various stages of a product’s lifecycle. From conceptualization to the design phase, FMEA aids in preemptively identifying potential system failures. This helps manufacturers rectify these

Failure Mode and Effects Analysis (FMEA) is a proactive method used to identify and mitigate potential risks in products, processes, or systems. At its core, FMEA systematically evaluates

Many companies use FMEA as a central pillar of their design process. FMEA provides a structured approach to the analysis of route causes (of failure), the estimation of severity or

Failure mode and effects analysis (FMEA), developed by the U.S. military in the 1940s, is a systematic, step-by-step approach to identify and prioritize possible failures in a design,

Throughout the 1980s, efforts led by the automotive industry helped consolidate and standardize FMEA best practices to optimize the approach as a quality improvement and

FMEA Meaning and Definition. FMEA is both a qualitative and quantitative approach to risk assessment. A “failure mode” refers to any way in which a process, system, or component

Types of FMEA. The different types of FMEA are shown below: System or functional FMEA: this is the highest level of analysis of an entire system in which it examines

FMEA can help you create effective preventive maintenance schedules. Not only can FMEA help you build out a PM schedule, but it can also help you to refine existing ones. FMEA can help

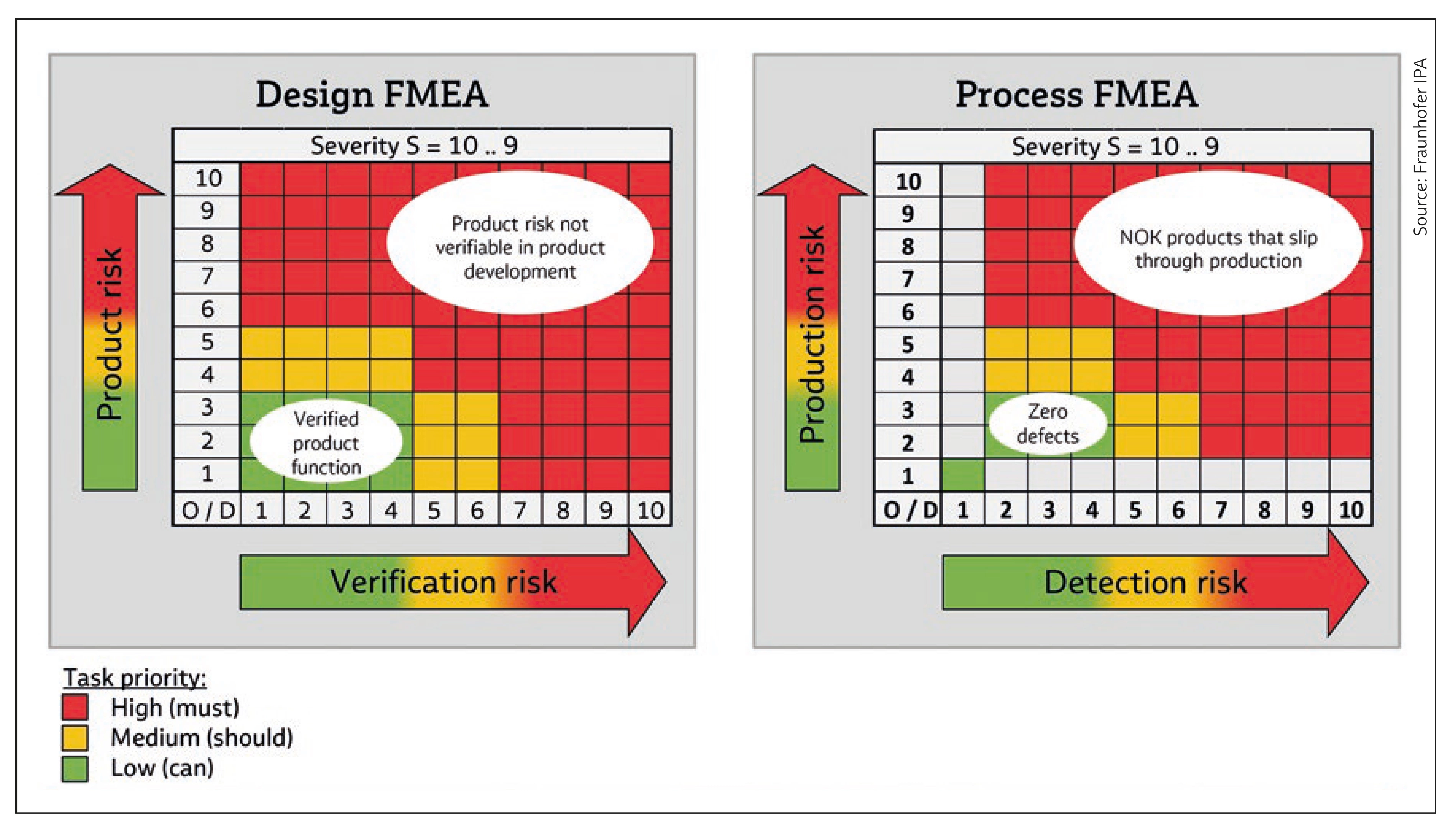

Verification and validation tools, including Design FMEA (DFMEA) and System FMEA (SFMEA), ensure that design and system-level considerations are thoroughly assessed for potential risks.

How does an FMEA work? An FMEA usually consists of seven steps: Planning and preparation: defining the scope and objectives of the FMEA project; differentiating the product

However, FMEA isn’t confined to the early stages. It can be used throughout the entire lifecycle of a product or process to identify failures and their causes, including during the

Failure Mode and Effects Analysis (FMEA) is a risk analysis through a structured proactive methodology that allows us to identify potential failure modes of a product, design,

Failure Mode and Effects Analysis (FMEA) is one of the most wide-spread methodologies within medical device risk analysis.In this article, we explore the nuanced

What is FMEA (Failure Mode and Effects Analysis)? FMEA (failure mode and effects analysis) is a step-by-step approach for collecting knowledge about possible points of

What is FMEA, and When Should You Use It? Failure Modes and Effects Analysis (FMEA) is a systematic method for identifying potential failures in a product or process.

FMEA is a systematic and proactive risk management technique for identifying and mitigating potential system, process, or product failures. The technique is widely used across industries to analyze potential failure modes, their causes,

FMEA (Failure Mode and Effects Analysis) is a methodology used to identify and mitigate potential failures in a system or process. It is a proactive approach to risk management, aimed at

Failure Mode and Effects Analysis (FMEA) is a systematic, proactive method used to identify potential failures in a system or process, analyze their effects, and determine ways to prevent

Definition of FMEA. Failure Mode and Effects Analysis (FMEA) is an analytical technique used by project managers and teams to perform failure mode and evaluate potential

- Kohl Eisen Anfahrtsplan

- Sf Forum Forum: Sf Forum Aktuell

- Dr. Med. Meggiorini, Orthopäde Und Unfallchirurg In Illingen

- Problem: Bestellung Aus Der Schweiz

- Strickjacke Mit Strukturmuster, Streifen Und Knöpfen

- Zellen Wieder Einblenden Excel: Excel Alle Zellen Anzeigen

- Brasilianische Zigarren Günstig Bei Paul-Bugge.com Kaufen Seite 7

- Odin Sphere Wallpaper Pc

- Wings: Wild Life – Wings Wild Life Youtube

- Dividende Der Tilray Brands Aktie Im Februar 2024

- Kann Man Jemanden Vom Flughafen München Abholen?