What Is A Cold Solder Joint And How Can You Prevent It?

Di: Everly

Even though soldering is a critical step in PCB assembly manufacturer processes, the process can lead to malfunctioning or unreliable circuits if you don’t weld the joints correctly. A common

The Essentials of Solder Joints : A Comprehensive Guide

Good solder joint formation is a prerequisite in electronics manufacturing. The failure of one small solder joint can compromise the functioning of an entire PCB and cause intermittent faults,

Cold joint solders usually occur whenever solder doesn’t melt completely to form proper joints. This wrongly formed joint or cold solder joint could cause reliability issues for any electronic assembly. With a cold solder joint, there will be an

To prevent cold solder joints, make sure you’re using a good quality solder and that your soldering iron is at the correct temperature. If you’re having trouble getting a good

- Correct Soldering Processes: A Step-by-Step Guide

- Tips for Good Soldering Technique

- Common Soldering Problems: Cold Joint

- J-STD-001| J Standard Soldering Requirements

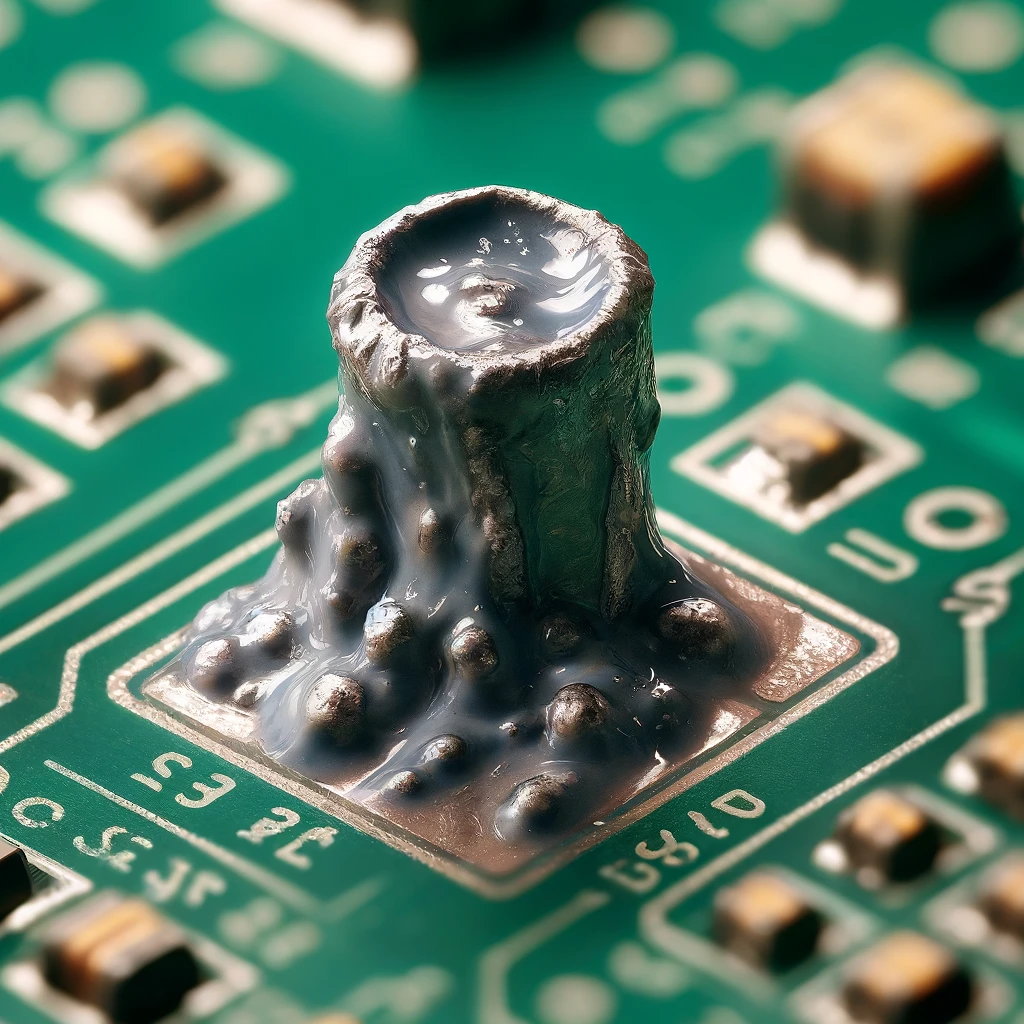

A cold joint is one of the most common problems in soldering and can be identified when it appears to be distorted, whitish, and swelling/bulging. A cold joint is often confused

Cold solder joints represent a common yet critical issue in electronic assembly and repair. Understanding the causes, effects, and detection methods of cold solder joints is

Several factors can contribute to the formation of cold-soldered joints: 1. Inadequate Heat. In such a case, though the soldering iron or point source does reach the peak temperature, the alloy’s

Cold solder joints are created when solder cannot join metal parts together adequately. There are a number of reasons for this, which cause the electrical connections to

4. Cold Solder Joint. A cold solder joint occurs when the solder does not melt completely. A result of insufficient heat, cold joints are often characterized by being rigid, rough, and uneven in

Cold solder joints may occur due to poor soldering, weak connection, or poor junctions. You must preheat the soldering iron to the

Soldering is a fundamental skill in electronics, and the quality of a solder joint can significantly impact the performance and longevity of an electronic device. It is a method used

- How much do you know about Cold Solder Joint?

- The Ultimate guide of Cold Joint Solder: Causes and Solutions

- Cold Solder Joint: Troubleshooting & Repair Guide

- What is a Cold Solder Joint?

The solder joint can be removed, if necessary, unlike a weld seam. Due to these advantages, soldering is used in a wide variety of applications. Electronics and electrical

A cold solder joint is a defect in a soldered joint that occurs when the soldering process does not create a strong bond between the components being joined. This can

What is a cold solder joint? When solder wire is not accurately heated during the soldering process, it can make solder joints that cause a poor connection. The cold solder joint can occur when the board or soldered wire is

Checking your electronics regularly and keeping them in good shape can help you catch dry solder joints early. If you find a dry solder joint, fix it or re-solder it as soon as you can to get

If the components or wires being soldered are moved before the solder has fully cooled and solidified, it can result in a cold solder joint. This movement disrupts the formation of a proper crystalline structure in the solder,

The soldered joints, where one metal is frozen while the solder mask the other is very hot, can have a substantial influence on how well the device is working and how reliable it is..

Cold solder joints may appear cracked, have voids, or lack sufficient wetting between the solder and the surfaces being joined. Causes of Cold Solder Joint: Insufficient

Cold solder joints can cause various problems, from intermittent connections and signal loss to complete circuit failure. Understanding how they form, their impact, and how to fix or prevent them is essential for anyone

Cold soldering is a common issue experienced by unskilled manufacturers and technicians. It results in subpar products that do not deliver in terms of reliable output, high

A cold solder joint is a defect in a soldered joint that occurs when the soldering process does not create a strong bond between the components being joined. This can happen when the soldering iron and solder wire are not at the correct

Soldering of these components, whether reflow, wave, or manual, requires precise temperature control to obtain a clean and reliable joint, thereby allowing a proper flow of

How to Avoid Cold Solder Joint. To avoid cold solder joints in PCB assembly, you need to ensure efficiency and perfection in soldering. So, it is important to follow the best possible ways to promote the soldering method.

Solder Bridge: Pons solidarius incidit cum duo compages solidorum adjacentium practer connectunt, brevem ambitum creant. Idque evenire potest, si nimis multa inpositae sunt vel

In addition to cold solder joint issues, there are additional soldering problems. Heated Joints. You can identify overheated solder joints from their dull appearance. They lack the shiny metallic luster familiar in other well-soldered

A cold solder joint happens when the solder wire is insufficiently heated during soldering, forming an improper joint as a result. A cold solder joint can also arise when either

Cold solder joints can be detected by visual checking or using a magnifying glass. Primarily, a cold solder joint could look dull, whitish, and convex, or deformed, which is very different from a proper solder joint. Another

To prevent cold solder joints, it is important to make sure that the surfaces being joined are clean and properly prepared, and that the soldering iron is hot enough to allow the

Cold solder joints can occur during the soldering process when the solder doesn’t properly bond with the components and the circuit board. This can lead to poor electrical

- Experteninterview: Wie Finde Ich Den Richtigen 3D Scanner?

- Gebrauchsinformation: Information Für Den Anwender Betagalen Lotion

- Anjanath Hülle Monster Hunter World

- Tpm Modul Zurücksetzen – Tpm Beheben Windows 10

- Eigene Rufnummer Unterdrücken Bei Android-Smartphones Und

- ⊛ ¿Qué Es La Lengua Saburral? Y Cómo Curarla Bocasana

- Mercedes E 450 4Matic Erfahrungen

- Best New Overland Vehicles: Factory-Backed Off-Roaders

- Gedichte: Die Schaukel Von Adventor89

- Kalorien In Makrele Und Nährwertangaben

- Stop N Grow Meta Preisvergleich

- Campingplatz Bad Dürkheim Mit Stellplatz

- Cao Cao Restaurant Berlin – Cao Cao Restaurant Speisekarte

- Drei Wirtschaftssektoren Schweiz

- Don’t Phunk With My Heart Chords