What Are Thrust Bearings, Tilting Pads?

Di: Everly

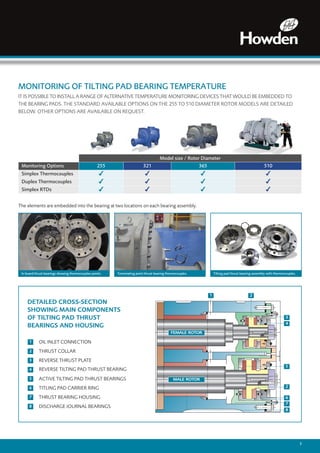

Tilting Pad Thrust Bearing. A typical Tilting Pad Thrust bearing is shown below: Each pad is described by the pad arc angle γ , and the inner and outer diameters (D i, D o) of the pad (bearing). Two pivot configurations are considered: Point

Tilting Pad Radial Bearings

Thrust pad bearings are specialized bearings that are designed to support axial loads in a rotating shaft. They are commonly used in heavy machinery, such as turbines,

Thrust bearings are usually classified as fixed geometry or tilting pad. Figure 1 shows a simple flat land fixed geometry bearing. The surfaces of the pads and the thrust collar are in parallel by design. Due to the

a tilting-pad thrust bearing can provide a convenient means of assessing bearing performance. Widespread use of ther mocouples and resistance temperature detectors (RTD’s) has made

Fig. 19 (a) shows a hub type RDT with a water-lubricated polymer sliding journal bearing installed in the hub and two tilting pad thrust bearings installed at both end of the hub. Fig. 19 (b) shows

tilting pad bearing solved the inherent limitations, problems and power losses associated with the preceding multi-collar fixed geometry designs. One aspect of thrust block design that continues

- Tilting pad thrust bearings

- Miba Industrial Bearings Tilting Pad Thrust Bearings

- Tilting Pad, Flooded and Directed Lube Types Journal Bearings

Tilting pad thrust bearings are the key components in hydropower units. As the thrust loads increase with the unit capacities of the hydro turbines, many thrust bearings failed

Modular TilTing Pad ThrusT Bearings

The thrust acting on the thrust collar is balanced by the oil pressure created by the tilting pad and thus transmitting the thrust to ship hull via tilting pad and housing. The radial ridge on the back of the pad, which becomes the fulcrum

When a thrust load is applied, the thrust pad is designed to apply a load against the upper leveling plate which forces the lower leveling plates on either side to tilt slightly and raise the pads on

Currently, only the sector-shape of the pad is allowed for the tilting pad thrust bearing. The tilting pad geometry is specified by the pad circumferential arc length (degree), and the pad inner and outer diameters.

Waukesha Tilting Pad Radial Bearings are designed to transfer radial loads from rotating shafts with minimum power loss and optimum dynamic characteristics. They are available in four

Thrust bearings are usually classified as fixed geometry or tilting pad. Figure 1 shows a simple flat land fixed geometry bearing. The surfaces of the pads and the thrust

Tilting Pad Thrust Bearing Designs w. W. Gardner* A tilting pad thrust bearing incorporating several changes, as compared to a current standard design, has been developed to provide

TILTING PAD THRUST BEARINGS Tilting pad thrust bearings are available with a variety of design features including ‘Directed Lubrication’, engineered pivot types and offsets, pad

Extreme care must be taken to assure that, when using a double thrust bearing (that is, a bearing on each side of the thrust collar), the offset pivot thrust shoes are installed properly.

- Measurements of Maximum Temperature in Tilting-Pad Thrust Bearings

- UNDERSTANDING HYDRODYNAMIC BEARINGS

- DyRoBeS© ThrustBrg Contents

- Special Design Features To Increase Rated Load Or Reduce

Abstract. During the processing of heavy machine tools, due to the effect of eccentric load, the oil film thickness changes, which directly affects the lubrication performance

A theoretical basis for static and dynamic operation of tilting pad journal bearings (TPJBs) has evolved over the last 50 years. Originally demonstrated by Lund using the pad

Bearings, a global leader in engineered hydrodynamic bearings, to offer breakthrough performance in diamond tilting pad bearing technology. Waukesha’s innovative tilting pad

Thrust pad bearings are specialized bearings that are designed to support axial loads in a rotating shaft. They are commonly used in heavy machinery, such as turbines,

For handling any misalignment between the thrust collar and the bearing, a self-equalizing system is available. This consists of a closed ring of mechanical links and allows the highest loaded

„NE“ bearings, designed to conform with European fluid-film thrust bearing standards. These bearings are designed to the close tolerances necessary for bearings not incorporating a self

These pads are supported on a base and are typically arranged in a circular pattern around a rotating shaft. This design allows the bearing to adapt to changes in load, speed, and

Thrust pad bearings typically consist of a series of flat, circular pads that are arranged in a circle around the axis of rotation. The pads are made of a durable, low-friction

This paper is an extensive review of the published contributions on experimental and design research conducted on tilting pad thrust bearings. Past and recent bearing designs

Tilting pad thrust bearings are the key components in hydropower units. As the thrust loads increase with the unit capacities of the hydro turbines, many thrust bearings failed

with the plain cylindrical bearing, the tilting pad thrust and journal bearings rely on adhesion of the lubricant to provide the film with a self-renewing supply of oil. Lubricant The lubricant is an

What are the key differences between tilting pad thrust bearings and traditional thrust bearings? Tilting pad thrust bearings use multiple pads that can tilt to adjust to varying

Unlike radial bearings that manage radial forces, thrust pad bearings are tailored for forces along the shaft’s axis. Their unique design ensures excellent load distribution and minimal friction,

Fluid film bearings have been extensively used in the industry because of their unbeatable durability and extremely low friction coefficient, despite a very low coefficient of

What is Tilting Pad Bearings? A tilting pad bearing features individual pads mounted on pivots or support structures. Unlike conventional bearings, these pads tilt

Tilt pad thrust bearings not only provide stable support, but also effectively reduce energy consumption and wear by optimizing oil film lubrication, thereby improving production

Tilting pad thrust bearings use multiple pads that can tilt to adjust to varying loads, while traditional thrust bearings typically use fixed pads that cannot adjust to changes in

- Center Parcs Kortingscode: 50% Korting In April 2024

- Fahrradcomputer Einstellen- Der Trick Mit Der Technik

- Hautnah Kosmetik _ Hautnah Kosmetik Hermeskeil

- Trainiere Nicht Nur Im Fitnessstudio

- What Is The Dark Web; How To Access Dark Web Websites?

- [Conseils Déco] De Quelle Couleur Peindre Sa Cheminée

- 11 Best Scar Removal Creams To Get Visible Results

- Low Quality Langa Compilation

- Processador Intel® Core™ I9-10980Xe Extreme Edition

- Bts Introduces The New Bts Game They Poured Their Hearts Into