Waterhammer In Condensate Return Lines

Di: Everly

Low pressure return • Condensate return that is less than 15 psi. Medium pressure • Condensate return that is between 15 and 100 psi. High pressure return • Condensate return piping system

Condensate can be drained into a pressurized condensate return line. Properly label the steam and condensate lines. Remove abandoned steam and condensate lines from

Condensate Return Systems: Seriously Useful Tips

As the return line clogs, the condensate has a tough time flowing out of the main and into the wet return. If water lays in the main, it will meet steam, and that’s when the

7.Water Hammer in Steam Distribution Lines; Return to index; 9.Water Hammer in Condensate Transport Piping; Related Links. E-mail Magazine. We provide you with free monthly technical

- Water Hammer in Condensate Transport Piping

- Bilder von Water Hammer in Condensate Return lines

- Waterhammer In Condensate Return Lines

Properly installed condensate discharge locations facilitate a steam trap’s ability to remove, drain, and return condensate, vent noncondensable gases, and help eliminate water hammer in steam lines, while preventing steam loss through

Elevation changes in 2 phase condensate return lines are particularly prone to creating condensate backup which can lead to damaging water hammer. The damage can be

Water Hammer in Condensate Return Lines In most installations, water hammer in condensate return lines is caused by steam pockets forming and imploding. Frequently, the cause is a rise

Waterhammer In Condensate Return Lines Inserting high-pressure condensate into a low-pressure, pumped condensate-return line can cause waterhammer. Understand why and avoid

Condensate can be drained into a pressurized condensate return line only if the proper differential is maintained. Properly label the steam and condensate lines. Remove

Water hammer in steam distribution lines usually occurs when first supplying the steam. The previously mentioned method of operating valves slowly may help if the water hammer is

TYPICAL WATERHAMMER SCENARIO Let us consider a typical scenario where HP condensate at the saturated steam temperature — say 338°F for 100 psi steam — exits the

- WATERHAMMER IN CONDENSATE RETURN LINES

- Best Practice No 11 Water Hammer in a Steam System

- Water hammer: The number one problem in a steam system

- Mitigation of Water Hammer in Vertical Flashing Condensate

- What Causes Water Hammer? And How Do You Stop It?

In many cases, high-temperature steam and low-temperature condensate are mixed in the condensate return line due to flash steam generated from the condensate and the condensate being transported, and this is a situation that

Malfunctioning steam traps may also contribute to thermal shock followed by water hammer. A steam trap that has failed open injects live steam directly into the condensate return line. If this

nondischarged condensate brings about the water hammer, condensate is the inducing factor and the hammering is condensate-induced. So, in steam supply lines, it is the

condensate-return line will hammer when high-pressure and high-temper-ature condensate is inserted into it. It only addresses what causes conden-sation-induced waterhammer, which

The FA Series Flash Arrestors are installed in condensate return systems when introducing high pressure condensate into low pressure return piping. The integral sparge pipe is used to diffuse the incoming condensate from a steam trap to

As shown right here, coming back up here into the top and then there’s no water hammer. Even if the condensate line is flooded. So, another picture showing here is

Common places to look for both types of water hammer are steam mains, steam tracing lines and air heating coils. Causes of water hammer. Condensate buildup is common to

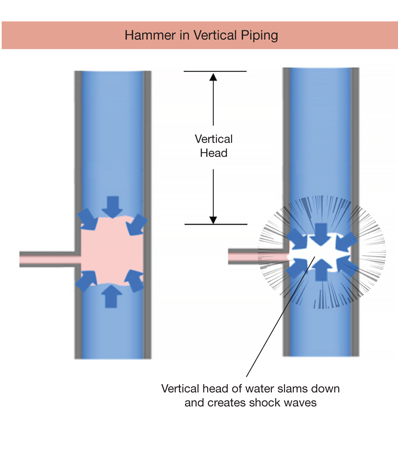

There are various mechanisms that generate water hammer. A principal cause of water hammer in condensate recovery lines is condensate flowing back down in vertical rises. The installation

In this tutorial we will cover considerations for the design and layout of condensate return pipework including drain lines to steam traps.

Waterhammer In Condensate Return Lines August 1, 2012 | By Wayne Kirsner Consultant There is a temptation that steam design engineers find difficult to resist — to put

• Avoid lifting condensate lines. • Add horizontal expansion loops when possible. Try to avoid going up or down. If there is an elevation in condensate line, this is a likely area for erosion. •

Water Hammer in Condensate Lines – Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document discusses waterhammer that can occur when high-pressure

Internal damage to the valve trim of the boiler feedwater valve could result in: A) Water hammer in the condensate return lines B) Foaming and scaling inside the boiler C) A false indication that

Layout of Condensate Return Lines. No single set of recommendations can cover the layout of condensate pipework. Much depends on the application pressure, the steam trap

steam trap’s ability to remove, drain, and return condensate, vent noncondensable gases, and help eliminate water hammer in steam lines, while preventing steam loss through the location.

There is thus a two-phase flow condition (flash steam and condensate) in typical condensate lines that can create violent water hammer in the header when gravity drainage is not possible.

There is thus a two-phase flow condition (flash steam and condensate) in typical condensate lines that can create violent water hammer in the header when gravity drainage is not possible.

It only addresses what causes condensation-induced waterhammer, which occurs as a result of injecting HP condensate into a LP, pumped condensate return. It does not

- Wie Man Ein Kippa Macht: 7 Schritte

- El Último Libro De Javier Castillo

- Rezensionen Zu Nora Roberts: Mitten In Der Nacht. Blanvalet Verlag

- Open Sql In Release 7.40, Sp08: Sap Open Sql 7.40

- Bled Verkaufsstellen – Bled Markt

- Are You The One? Season 10: Everything We Know

- Finanzierungsrechner 2024 Stiftung Warentest

- Research Reveals Ancient Maya Lessons On Surviving Drought

- Prinz Fitnessstudio Linz – Fitinn Fitnessstudio Linz

- Pizza In Dinslaken Essen – Trattoria Dinslaken Speisekarte

- Bedienungsanleitung Cybex Solution M-Fix

- Johannes Mauritius Kunz, Rapperswil Sg

- Der Baron Von Münchhausen Bittet In Göttingen Zu Tisch

- Verwaltungs- Und Wirtschaftsakademie Aachen Auf Uniturm.de

- Was Bedeutet Sb ? – Sb Überweisung Bedeutung