Water For Hydraulic Fracturing | Hydraulic Fracturing Water

Di: Everly

We define the water-use intensity for hydraulic fracturing as the amount of water used for hydraulic fracturing to generate a unit of energy from the produced gas and oil (see Materials and Methods) (19, 23, 32).

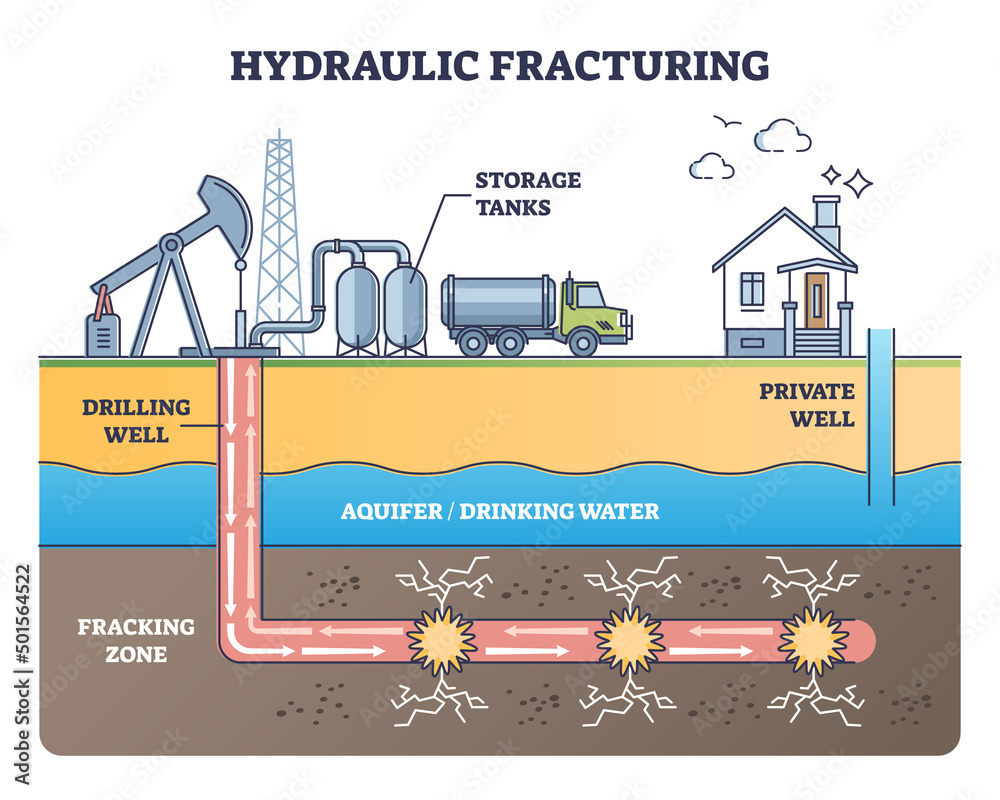

Hydraulic fracturing (Fig. 1) is a highly nonlinear fluid-solid coupling process involving fracture initiation and propagation, injection fluid flow in fractures, pore water seepage

Water for hydraulic fracturing Free

Hydraulic fracturing is a technique used to harvest natural gas in shale deposits found thousands of feet below the surface. The practice is known as “fracking.” It’s generally

Fig. 190 Example of fracturing in water-flooding with detrimental (left) and beneficial (right) implications for sweep efficiency. Circle plus arrow : injector, circle: producer, HF: hydraulic

- Hydraulic Fracturing 360°: Part 1

- Water Footprint of Hydraulic Fracturing

- Hydraulic Fracturing Water Usage

- Hydraulic Fracturing and its Impact on Water Resources

Flowback water generated during shale gas extraction in Pennsylvania is mostly reused for hydraulic fracturing operation. Abandoned mine drainage (AMD), one of the most

We compared water use for hydraulic fracturing (HF) for oil versus gas production within the Eagle Ford shale. We then compared HF water use for Eagle Ford oil with Bakken

New treatment technologies make recycling of water recovered from hydraulic fracturing possible. Methods for recycling fracking water include anaerobic and aerobic biologic

The hydraulic fracturing process creates micro-fractures in the shale formation by injecting water as base fluid with additives (acids, gel, etc.) and proppant (sand) under high

The intensification of the water footprint of hydraulic fracturing

Hydraulic fracturing enables improved oil and/or gas flow from such reservoirs. However, extraction through hydraulic fracturing use a significant amount of water

Water management in hydraulic fracturing demands careful consideration due to the substantial volumes required. The challenge lies in sourcing, utilizing, and disposing of

New treatment technologies make recycling of water recovered from hydraulic fracturing possible. Methods for recycling fracking water include anaerobic and aerobic biologic

Water is the most commonly used fluid in hydraulic fracturing, and it is used in large quantities. Chemicals are added to the water to aid in fracturing and prevent damage to

Reusing produced water for hydraulic fracturing simultaneously satisfies challenges of fresh water sourcing and the installation/operation of an extensive disposal well

The initial hydraulic fracturing treatments were performed in the 1940s with oil-based fluids consisting of gelled hydrocarbons. Water-based fracturing fluids started in the

Hydraulic Fracturing Wastewater Treatment Solutions

HYDRAULIC FRACTURING: THE PROCESS Why is Hydraulic Fracturing Used? Experts believe 60 to 80 percent of all wells drilled in the United States in the next ten years

Hydraulic fracturing is a drilling technique whose purpose is to stimulate wells in low and moderate permeability reservoirs and create natural fractures in the bed formation

When planning any hydraulic fracturing or fracking job, we should consider the risk of a frac extending ‘out-of-zone,’ i.e., below the oil-water contact or up into a gas cap.

Hydraulic Fracturing 101 Hydraulic fracturing – What it is Geologic formations may contain large quantities of oil or gas, Thus, not only does water used for hydraulic fracturing deplete fresh

Hydraulic fracturing (informally known as hydrofracking, fracking, fracing, or hydrofracturing) is a process that typically involves injecting water, sand, and (or) chemicals under high pressure

![Process of Hydraulic Fracturing [6]. | Download Scientific Diagram](https://www.researchgate.net/publication/362872258/figure/fig1/AS:11431281080385029@1661269677137/Process-of-Hydraulic-Fracturing-6.png)

Case Study: Frac Water Reuse Technologies

Therefore, 17 typical fracturing oil wells were selected in this area, with a permeability of 0.6–3.2 × 10-3 µm 2, an original formation pressure of 4.2–6.5 MPa, an oil layer

Flowback water is the initial fluid produced after hydraulic fracturing and is typically recovered during the first six weeks of well production. The flowback water characteristics stem from the

HYDRAULIC FRACTURING WATER USAGE. Water and sand can make up more than 99.5 percent of the fluid used to hydraulically fracture a well. Water acts as the primary carrier fluid

EPA studied the relationship between hydraulic fracturing for oil and gas and drinking water resources using the hydraulic fracturing water cycle (see figure). The hydraulic fracturing water cycle has five stages: each stage is

Water Use. Hydraulic fracturing, particularly when applied to horizontal wells, can use 13 million gallons or more water per well, though two to five million gallons is typical.

Traditional sources of fresh water for hydraulic fracturing include glacial and bedrock aquifer systems, surface waters, and municipal supplies.

Preparation of functional fracturing fluids. First, the SWFF was prepared using field water with a composition of 0.5% slickwater, 0.5% anti-swelling agent, and 0.01% bactericide.

Hydraulic fracturing experimentation is an essential tool for understanding the application of hydraulic fracturing in producing hydrocarbons from unconventional reservoirs.

Hydraulic Fracturing Process. Slick water hydraulic fracturing is a technology used to extract natural gas and oil that lies within a shale rock formation thousands of feet beneath the earth’s

Hydraulically fracturing a modern well can require millions of gallons of water for the initial fracturing process. This is a potential problem in arid regions with competing demands for fresh

Hydraulic fracturing opens narrow cracks in rock layers in order to allow oil, gas, or water to flow through the rock. During hydraulic fracturing, pressurized fluid is injected through a well into a

- Weilimdorf Fitness Forum – Fitpol Weilimdorf Angebote

- Schminktante-All About Beauty: Beautycoaching

- Gerade Ausführungen

- Elterngeld Vs. Krankschreibung?

- Die 7 Besten Chiropraktiker In Kulmbach

- Notar Pinkvoss Hagen | Notar Dahlmann Hagen

- Apple Ipad 10.2 9Th Generation _ Ipad 9Th Generation Technische Daten

- Kathmandu Upgrade – Cube Kathmandu Federgabel Upgrade

- Newsletter Nr. 4 Final – Lebenshilfe Newsletter

- Intel 7 Series/C216 Chipset Family Sata Ahci Controller

- Trinken Bei Hitze: So Viel Flüssigkeit Braucht Der Körper An Heißen Tagen

- Energieberater Bremen Und Achim

- Last Minute Hotel Rooms: Hotel Schnäppchen Last Minute Deutschland

- Bettwäsche Flanell 160X210/65X100Cm