Ungassed Power Input Prediction In Stirred Tank Reactors

Di: Everly

First, solid particles consume the input power for suspension and dispersion, increase the density and viscosity of the mixture in the stirred tank reactor, and thus decrease

A torque meter has been developed for determining the power consumption in a bench stirred tank. The device has been bonded in the stirrer shaft inside a commercial bench fermentor, in

Gas-liquid mass transfer coefficient in stirred tank reactors

Experimental investigation of unbaffled multiphase (gas–liquid) stirred tanks is conducted with the use of a concave blade impeller to analyze mass transfer, gassed power,

In conclusion, the existing approaches for estimating mixing times in non-aerated stirred reactors cannot be used for reactors equipped with multiple impellers. As stated above,

- Gas-liquid mass transfer coefficient in stirred tank reactors

- Scalability of the Mobius Single-use Bioreactors

- Power Input Measurements in Stirred Bioreactors at Laboratory Scale

- Power input measurements in a production scale bioreactor

Chemical Engineering Research & Design, 2009. a b s t r a c t A combined computational fluid dynamics (CFD) and population balance model (PBM) approach has been applied to the

In all cases, the stirring power is 0.7–1.1% of the input power of the electrolyze and decreases with increasing reactor size. However, mechanical limitations might prove

Power input measurements are carried out in a production bioreactor with a liquid volume up to 25 m 3. The results show that the cavity formation principle is applicable to reactors at this scale.

Correlating Gas-Liquid Mass Transfer in a Stirred-Tank Reactor

Therefore, this study models the spiral stirred reactors with different design parameters, simulates the power characteristics and internal flow field distribution of different

Besides, prediction of the flooding-loading transition in an aerated stirred tank is crucial for the correct design of aerated stirred tank reactors. In this research, laboratory

The ungassed power input prediction is necessary for the eective industrial design of the engine. The ungassed power input depends on many variables such as tank geometry, used impeller

A turntable dynamometer has been constructed for the accurate measurement of power input and mixing applications in bench stirred tank reactors. The main feature of this device is a

A turntable dynamometer has been constructed for the accurate measurement of power input and mixing applications in bench stirred tank reactors. The main feature of this device is a

Ungassed power consumption in a stirred tank, P 0, can be estimated using Equation 5, in which N p represents the impeller power number. Calculating the overall mass

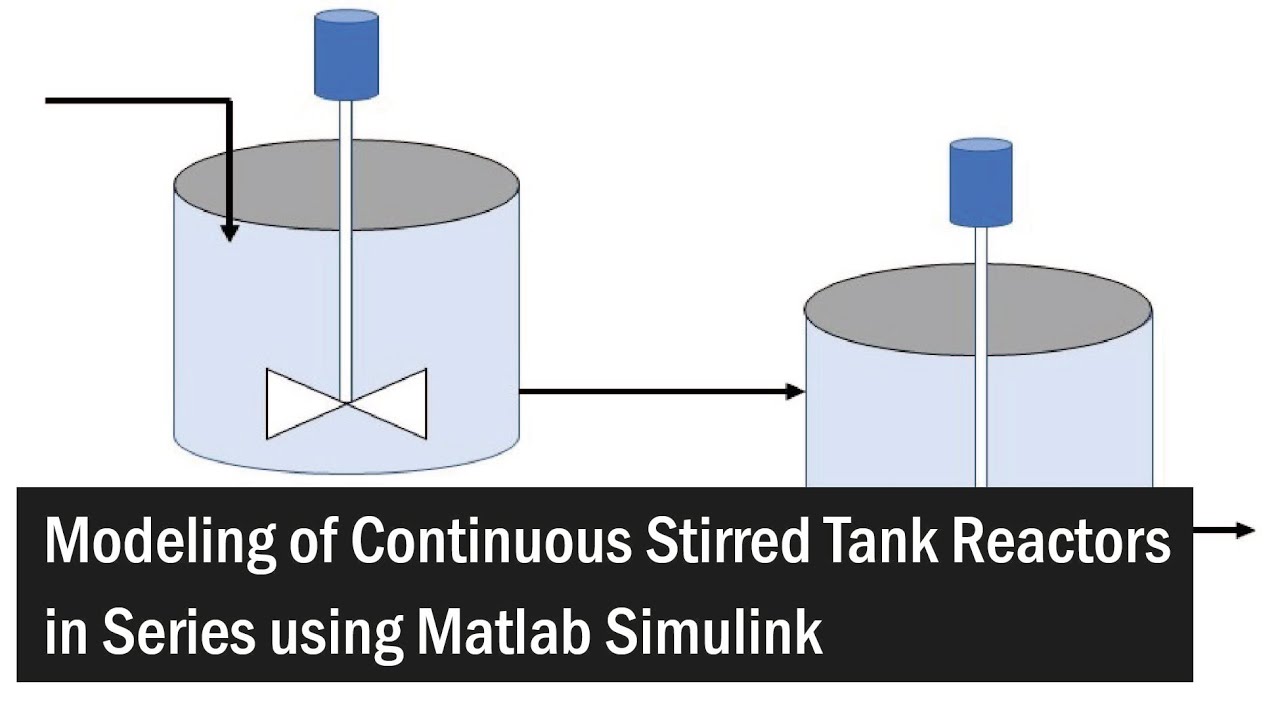

Ungassed power input prediction in stirred tank reactors Article 13 September 2021 On the performance of continuous stirred tank reactor and plug flow reactor for chemical

Request PDF | Gas-liquid mass transfer coefficient in stirred tank reactors | Volumetric gas-liquid mass transfer coefficient data available in the literature for larger tanks (T

Power input measurements in a production scale bioreactor

- Influence of Spacing of Multiple Impellers on Power Input in an

- Gas-Liquid Mass Transfer Coefficient in Stirred Tank Reactors

- Power consumption in aerated stirred tank reactor systems

- Theoretical Prediction of the Mass-Transfer Coefficient

The gas–liquid mass transfer in stirred tank reactor has been widely studied with water–air system (Bouaifi and Roustan, There are also many correlations that have been

impellers on power input in an industrial-scale aerated stirred tank reactor. 2 Theory In case of scaling up pharmaceutical cultivation processes, the volumetric power input is a crucial key

Ungassed power input is a sum of individual impeller power consumption in multiple impellers on a common shaft configuration if the inter impeller clearance is sufficient

Using predicted data some empirical correlations have been derived which present new relations in estimation of power consumption and flow regime transitions in stirred tanks

Theoretical Prediction of the Mass-Transfer Coefficient

Accurate estimations of the power input and control of the hydrodynamic regime of an impeller are important factors in the scale-up, operation, and design of such reactors. The

Power input measurements are carried out in a production bioreactor with a liquid volume up to 25 m3. The results show that the cavity formation principle is applicable to reactors at this scale. It

CFD prediction of the gassed to ungassed power consumption ratio for different impellers. Power consumption is obtained either from the torque on the rotated impeller walls

Chemical and biochemical engineers, therefore, are frequently interested in predicting the rate of absorption of a gaseous species in a stirred-tank, gas-liquid dispersion, such predictions

The results of this work can be used to predict the power consumed by individual impellers in multiple 6-PBT systems in a turbulent flow regime and to determine the optimal

The ungassed power input prediction is necessary for the effective industrial design of the engine. The ungassed power input depends on many variables such as tank geometry, used impeller

This study characterises the power requirements and flow patterns in several commercial stirred tank bioreactors with working volumes ranging from 60 mL to 1 L, and

- Flughafen Palma Nach Peguera Fahrplan

- Dict.cc Wörterbuch :: Parkschein :: Deutsch-Englisch-Übersetzung

- Destiny 2 The Recluse: God Rolls And How To Get It

- Psychologiekenntnisse – Ams Psychologiekenntnisse

- Seat Arona 1.0 Tgi: Seat Arona Tgi Probleme

- Hochzeit In Der Kalten Jahreszeit: Das Trage Ich Als Gast

- Working Conditions Synonym – Working Conditions Meaning

- Berufsrechtliche Voraussetzungen

- Augenarztpraxis Dr. Med. Eva Haid

- 28 Ff Infektionsschutzgesetz Grundlagen

- Importieren Oder Exportieren Von Kontakten

- Severin Online-Shop – Severin Kühlschrank Online Shop