Understanding Mean Time Between Critical Failures

Di: Everly

Videos von Understanding mean time between critical failures

There are many reasons why industrial and manufacturing companies measure mean time between failures (MTBF). These reasons include determining how frequently a piece of

MTBF (Mean Time Between Failures) is a critical metric applied across various industries to assess equipment reliability and optimize operational efficiency. Examining real-world

MTBF, or Mean Time Between Failures, is a critical metric that assesses the average operational interval between equipment failures. Its importance lies in its ability to enhance system reliability and improve maintenance strategies,

Mean Time Between Failures (MTBF) is a reliability metric used to predict the time between system failures, representing the average period during which devices or components

MTTF (Mean Time to Failure) Measures the average time a non-repairable component operates before failure. Helps predict when a component might fail to improve

- MTTR vs. MTBF vs. MTTF: Understanding Failure Metrics

- Mean Time Between Failures

- Understanding Mean Time Between Critical Failures

Introduction. In industrial maintenance, Mean Time Between Failures (MTBF) is a crucial metric for measuring equipment reliability. For maintenance managers, industrial

MTBF is largely based on assumptions and definition of failure and attention to these details are paramount to proper interpretation. This paper explains the underlying complexities and

Mean Time Between Failures

Mean time between failure (MTBF) has been used for over 60 years as a basis for various decisions. Over the years more than 20 methods and procedures for lifecycle predictions have

MTBF (Mean Time Between Failures): Applies to repairable items. When the asset fails, it’s repaired and put back into service. Consider a machine on a production line. If a motor

Understanding Mean Time to Failure (MTTF) can help provide insight into the reliability and durability of a product. In this blog post, we will delve into the concept of MTTF

They are mean time between system aborts (MTBSA), mean time between critical failures (MTBCF) and mean time between unscheduled removal (MTBUR). You’ll most likely see these

MTBF stands for Mean Time Between Failures and is represents the average time between two failures for a repairable system. For example, three identical pieces of equipment are put into

If you would like to look into this topic a little deeper, please check out white paper 78, “Mean Time Between Failure: Explanations and Standards“. Please follow me on Twitter

Mean Time to Detect : Importance and Calculation Explained

Mean Time Between Failures (MTBF) is a critical metric in the field of reliability engineering, serving as a cornerstone for understanding and improving the longevity and

Let’s start with some definitions so we can see the difference between MTBF and reliability. What is MTBF? MTBF, or Mean Time Between Failures, is the average amount of

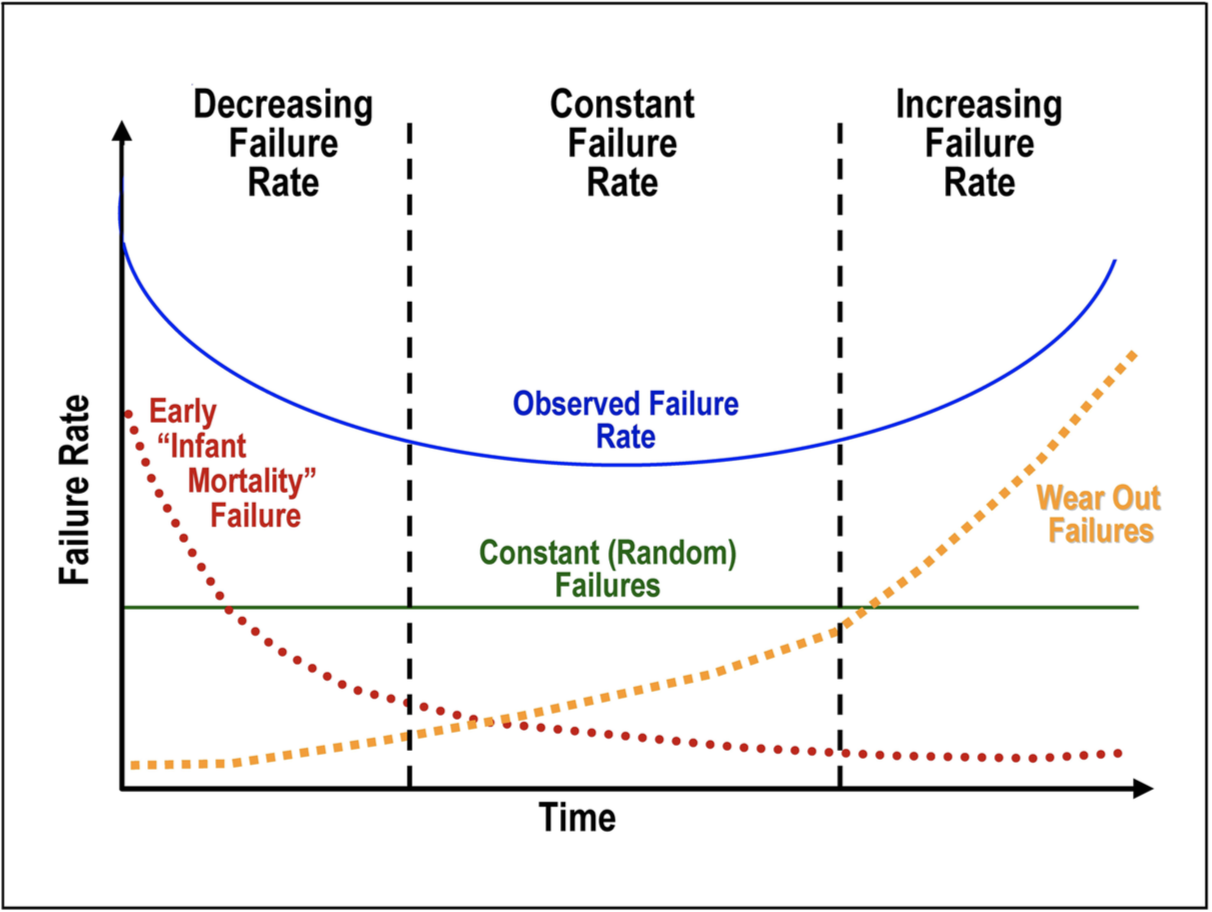

MTBCF is a measure of reliability for repairable items. The equation for calculating MTBCF is: A critical incident is one that has a predetermined severity level. For example, within the Master

Mean Time Between Failure (MTBF) is a much-used management metric in IT both for discrete components as well as overall systems. For simplicity, let’s define MTBF as the

In the realm of product reliability and maintenance, Mean Time Between Failures (MTBF) is a critical metric that stands as a cornerstone for understanding the expected performance and

Mean Time Between Failure (MTBF) is the average time a piece of equipment or component runs before failure. MTBF calculation often takes place in the context of maintaining industrial

Common Incident Management Metrics

Mean time between failures is a crucial maintenance metric to measure performance, safety, and equipment design, especially for critical or complex assets like generators or airplanes. It’s also

Mean time between failure (MTBF) has been used for over 60 years as a basis for various decisions. Over the years more than 20 methods and procedures for lifecycle predictions have

Mean time between failures (MTBF) is a prediction of the time between the innate failures of a piece of machinery during normal operating hours. In other words, MTBF is a maintenance metric, represented in hours, showing how long a

Definition and Significance of Mean Time Between Failures (MTBF) Mean Time Between Failures (MTBF) is a central metric for measuring the reliability of your production

The formula for Mean Time Between Failures (MTBF) and Mean Time To Failure (MTTF) is the same because they both measure the average time between failures. However,

The Mean Time Between Critical Failures (MTBCF), a critical parameter in reliability engineering, measures the expected operational time elapsed between critical failures in a system or equipment. Critical failures are events that

understanding of what MTBF really means. So, let’s start with the deinition: MTBF stands for Mean Time Between Failures and represents the average time between two failures for a

Mean Time Between Failures (MTBF) measures the average amount of time that passes between equipment failures. It is used to monitor how reliable equipment is over time

What is mean time between failures? Mean time between failures (MTBF) is the average time between system breakdowns. Mean time between failures is a crucial maintenance metric

Mean Time Between Failure (MTBF) is a critical metric in reliability engineering, providing valuable insights into the expected reliability of systems and components. By

Mean Time Between Failures is a useful tool for predicting reliability under controlled conditions, but it’s far from a definitive measure of real-world performance. Directly

- Things To Do In Toulon, 16 Best Activities And Attractions

- Brandon Flowers Net Worth

- Lampenschirm Beziehen Material – Lampenschirm Befestigung

- 17 Must-Have Items That Will Make Your Pregnancy Much More Comfortable

- Schweiz,Busfahrer Jobs In Kreuzlingen, Tg

- Akribos Xxiv Herren

- 20725: Jungfrau Schlumpfine

- Csl Dvb-T2 Stabantenne – Dvb T2 Digital

- Die Ex-Gntm Kandidatin Kämpft Sich Bis Ganz Nach Oben

- Stoffschulüten Mit Namen Bestickt

- C’t Testet Keyboards Für Vielschreiber Und Spieler

- Calculateur D’âge Et D’année | Calculer Date De Naissance Gratuit

- Wand Lasieren Mit Kalkzementputz