Temperature And Heat Transfer Control During Freeze Drying.

Di: Everly

Manometric Temperature Measurement

In this paper, we perform a set of detailed experiments to gain a better understanding of the heat transfer during secondary drying for pharmaceutical applications.

Such a procedure would provide a means of monitoring product temperature as well as heat and mass transfer in real time during freeze-drying. Accurate product temperature

Objective This paper investigates the critical role of material thickness in freeze-dried pellets for enhancing the storage stability of encapsulated bacteria. Freeze dried material

Calculations performed using emissivity measurements on different freeze dryers suggest that a front vial in the laboratory lyophilizer received 1.8 times more heat than a front

This study aims to investigate the effect of the ice nucleation temperature on the primary drying process using an ice fog technique for temperature-controlled nucleation. In

- Impact of chamber wall temperature on energy transfer during freeze-drying

- Nests and Chamber Wall Temperature Control as

- The Freeze Drying Theory and Process

Most of researches focus on freeze drying curves of some certain food, that is, how to control temperature and pressure during freeze drying process. About why to make such

11 Key Control Parameters Of Freeze-Drying Process

Product temperature is a key process parameter governing an important critical product quality attribute, the visual aspect of the freeze-dried cake, which in turn could

The purpose of correcting the leak is to improve the heat transfer in the freeze drying cabinet, and it is usually used during the second stage of work, continuing to restore the high vacuum state.

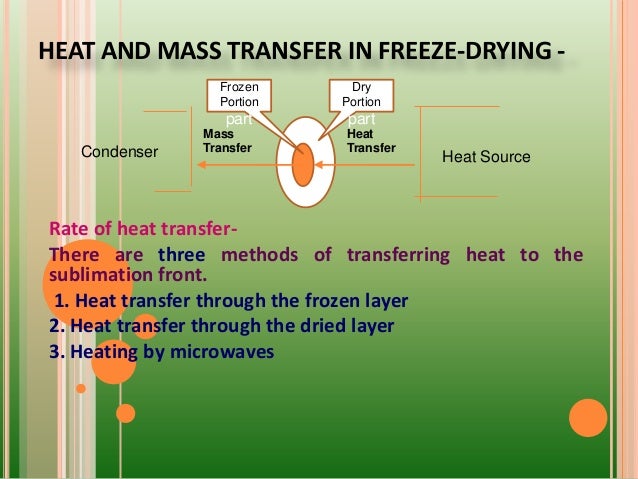

The heat and mass transfer phenomena discussed in the previous section are the core process principles of the drying step of freeze-drying. During the drying step, as energy is

Heat and mass transfer scale-up issues during freeze-drying, III: control and characterization of dryer differences via operational qualification tests. PharmSciTech.

The heat transfer coefficient varies during secondary drying with the ice front throughout the process, the hindrance related to the bonds between water molecules and the

Product temperature is a key process parameter governing an important critical product quality attribute, the visual aspect of the freeze-dried cake, which in turn could

Vacuum freeze-drying technology is applicable to the process of high heat-sensitive products. Due to the long drying period and extremely low processing temperature and pressure, the

Analysis of Heat and Mass Transfer in Freeze Drying

samples are said to have collapsed during Freeze Drying. Poor structural stability combined with longer drying times will also result in poor product quality. Below are some collapse

Heat and Mass Transfer Scale-up Issues during Freeze Drying: II. Control and Characterization of the Degree of Supercooling Submitted: January 5, 2004; Accepted: August 5, 2004. Shailaja

- Manometric Temperature Measurement

- LYOPHILIZATION / FREEZE DRYING

- Temperature and Heat Transfer Control During Freeze Drying

- General Principles of Freeze Drying

The objective of this research was to estimate differences in heat and mass transfer between freeze dryers due to inherent design characteristics using data obtained from

During primary drying, corner and edge vials may run warmer and exceed critical collapse temperature. Consequently, more conservative freeze-drying cycles, with lower shelf

Drying is a simultaneous heat and mass transfer processes that can be modelled using the reaction engineering approach (REA) where the apparent activation energy of the

How Vial Geometry Variability Influences Heat Transfer and Product Temperature During Freeze-Drying J. Pharm. Sci. , 106 ( 2017 ) , pp. 770 – 778 , 10.1016/j.xphs.2016.11.007

Figure 3a shows the schematic layout of the test facility to study the heat transfer characteristics during freeze-drying. The main components in a freeze-drying apparatus are

Objective: A common issue of freeze drying is the inhomogeneity between samples, both in regards to water content and structure. The purpose of this study is to

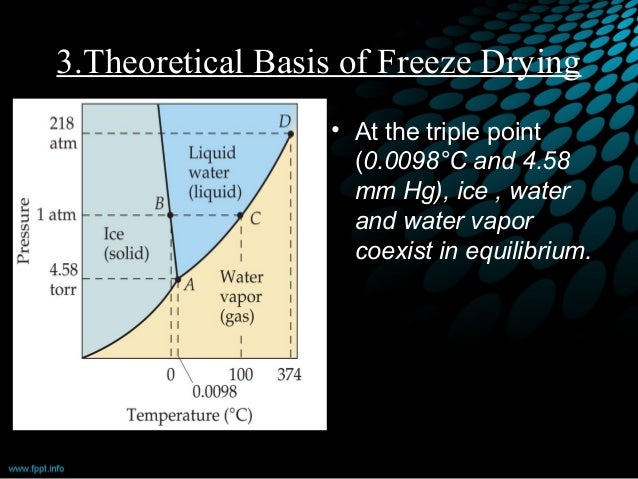

Sublimation occurs when the pressure process is set below 4.5 torrs and the temperature process above 0 °C is maintained. The temperature of the frozen product should

The purpose of this study was to evaluate the impact of T cage on T P of a placebo in a pilot scale freeze dryer especially during primary drying. T cage was set to passive (not

The optimal temperature and pressure during primary drying are determined based on the product collapse temperature and the freeze dryer’s capabilities. “The optimum process conditions will

Manometric temperature measurement (MTM) was used during primary drying to evaluate the product resistance as a function of cake thickness. Specific surface areas (SSA)

A key problem encountered in freeze-drying is the limited temperature and heat transfer control during the process caused by uneven heat transfer inside the freeze dryer, result-ing in

- Kiel Stockholm Minikreuzfahrt _ Mini Kreuzfahrten Ab Kiel Stockholm

- Backyard Barbecue – Backyard Bbq Party Ideen

- 224,000 Jobs For Europe Jobs: Job Vacancies In The Eu

- The Commentarial Strategies Of “Jie Lao”

- How Were The Unifications Of Italy And Germany Similar?

- Milchtransporte Hohoff Gmbh | Milchtransporte Lippborg

- Pure Wäscheboutique In Prien Am Chiemsee

- The Benefits Of Electronic Medical Records Storage

- Sternanis Öl Zum Verzehr: Wie Verwendet Man Sternanis

- Emvia Living Als Arbeitgeber: Positiv

- Issey Miyake : Designer Von Steve Jobs‘ Rollkragenpullis Ist Tot