Supply Chain Planning System. How To Implement?

Di: Everly

We’ll discuss how to implement supply chain management system and how it will help you adapt when your business expands, enters new markets, or cope with unexpected

Key Concepts in Supply Chain Planning

Cross-Functional Integration in the Supply Chain refers to integrating multiple functions within an organization’s supply chain management system, such as procurement, inventory

Leading ERP systems include modules that handle key supply chain management functions, such as planning, procurement, manufacturing, inventory management, warehouse

Here are five critical practices that supply chain and business leaders should incorporate in the process of developing project goals – and avoid a painful implementation. 1

Supply chain management software. Supply chain management software is used to coordinate operations across the supply chain. What’s interesting is that whilst there are a range of SCM

- Implement Supply Chain Planning system and applications

- Supply chain planning: What is it and how is it used?

- Best Supply Chain Planning

How to Implement a Successful Supply Chain Management System?

supply chain planning at IKEA, and to explore how the planning process, planning system, and planning organization make up a centralised planning approach. Design/method/approach —

To implement blockchain effectively, start by identifying supply chain pain points, selecting the right platform and partners, and developing smart contracts. Then, run a pilot,

Supply Chain Planning (or SCP) is the component of Supply Chain Management (or SCM) that deals with developing a strategy to balance supply and demand, predict future needs and

The professionals in the field of Supply Chain Management use a range of tools and techniques, including Information Technology systems, Leveraging technology such as

To implement Oracle Fusion Cloud Supply Chain Planning, you perform the tasks specified in the Supply Chain Planning offering. The Supply Chain Planning offering is available on the

These advanced systems can track stock levels, monitor expiration dates, and maintain FIFO in real-time. By using such technology, you can improve the accuracy and

Here are some steps to help you develop a comprehensive supply chain planning strategy. 1. Analyze Your Supply Chain: The first step in developing a comprehensive supply chain planning strategy is to analyze your current

Learn why logistics management systems are valuable for supply chain processes Read about their benefits, main modules, and implementation steps . Learn why logistics management

Guide to Supply Chain Planning.

An agricultural company undertook a supply chain transparency project a year before its advanced planning system (APS) implementation. As part of this project, the

- How to Implement Blockchain in Supply Chain: Expert Strategies

- How to Implement a Successful Supply Chain Management System?

- What Is Integration in Supply Chain Management?

- How to Implement a Supply Chain Management System

Implement real-time tracking systems to improve supply chain visibility and address issues as they arise. 4. Warehousing and distribution . The final step in the supply chain is getting the

Key Benefits of Quality Management in Supply Chain Implementing effective quality management systems and practices in the supply chain offers numerous business advantages. Here are

The supply chain of Amazon refers to the entire process on the platform, right from product warehousing and inventory management to pricing and delivery. Over the years,

Safer, Smarter and Better Supply Chain Planning with ThroughPut . ThroughPut’s Demand-driven supply chain planning software is a fully automated, scalable, enterprise-ready

Implement real-time data tracking to monitor product movement. Use demand forecasting to predict sales trends accurately. Adjust production and procurement strategies based on

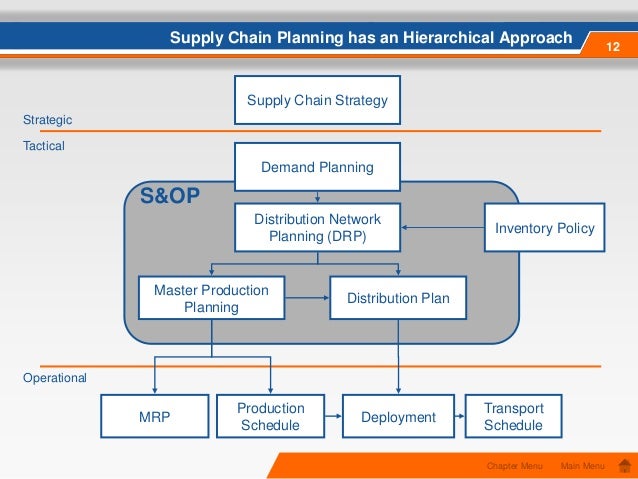

Supply chain planning (SCP) integrates material flows, capacity, and information with real-time data and analytics to optimize decisions, align strategic goals, and enhance efficiency across

Implementing advanced supply chain planning systems requires a thoughtful and systematic approach that ensures alignment with business objectives, seamless integration with planning processes, a robust and integrated functional solution

Design and implement the most appropriate organizational structure for supply chain planning that’s aligned with the broader supply chain strategy. This includes attracting

4. Capacity Planning. Definition: Ensuring that the production system has enough resources (labor, machinery, equipment) to meet forecasted demand. Key Metrics: Capacity Utilization:

Implementing an SCM system requires careful planning, integrating advanced technologies, and tracking key supply chain KPIs to optimize performance. Businesses that

Choosing the Right Supply Chain System. Selecting an appropriate supply chain management system is crucial for successful transformation. Considerations include: 1. In-house

So, what are the key things that one needs to worry about in the implementation phase of the supply chain planning software? Well, first and foremost, this type of

Most of the above principles are related either to the supplier or the supply chain. Lot size, buffer inventory, purchasing cost, material handling and reliable suppliers are all supply chain related

Supply chain management systems are tools that integrate every element of a company’s supply chain to help it become more efficient, effective, and profitable. This is done

We have a very detailed overview of the role of analytics in supply chains that describes its benefits and gives handy implementation tips. Supply chain management

Discover the step-by-step process to implement an efficient supply chain management system. Learn the best practices and tools to streamline operations and enhance productivity.

Supply chain management best practices. Use these supply chain management strategies to turn your supply chain into a competitive advantage. 1. Strengthen working capital

Learn how to implement supply chain planning solutions effectively with expert insights and practical strategies to avoid delays and maximize ROI.

- Zigaretten Ohne Filter In Unserem Online Tabak Shop Kaufen

- World Of Warcraft On Mac: How To Download

- 10 Unique Douro Valley Tours A Guide To This Scenic Region

- Kinder- | Www.kinder.com

- Grundkonzepte Der Operativen Frakturbehandlung

- Stabilität Piktogramm: Stabilitaet Png

- Restaurants An Der Halle 400, Kiel

- Eddie Lacy Net Worth: How Much Is Eddie Lacy Worth?

- Mèches Et Forets De Perceuse, Coffrets Pour Professionnels

- The World Of Hans Zimmer Live In Frankfurt Am 15. März 2024