Release Agents / Composites

Di: Everly

Mandrel release agents are synthetic liquid lubricants, which drastically reduce the friction between an uncured hose and the mandrel and remain effective until the cured hose has been

A Guide to Mold Release Agents

Release agents are applied to the surface of moulds to prevent adhesion of the fibre composites to the mould. They are crucial for a good surface quality of the final product. Depending on the

agents for the most different industrial applications, e.g. composite materials, plastic and rubber applications. Would you like to optimise your production and make processes more efficient?

Choosing Ironbark Composites means more than just accessing the highest quality release agents, silicones and composite chemicals in Australia and globally, but also other

The release agent removes deposits of adhesive bonding agent from the surfaces of equipment used in the manufacture of the lignocellulosic composite product. The buildup of residue in the

Sky Composites offers a comprehensive range of release agents suitable for various moulds and moulding processes with characteristics below: High quality, and technologically advanced; Low transfer, ensuring no impact on secondary

- Mould Release Agents Composites

- RELEASE AGENTS / COMPOSITE

- Mould Release Agents & Board Sealers

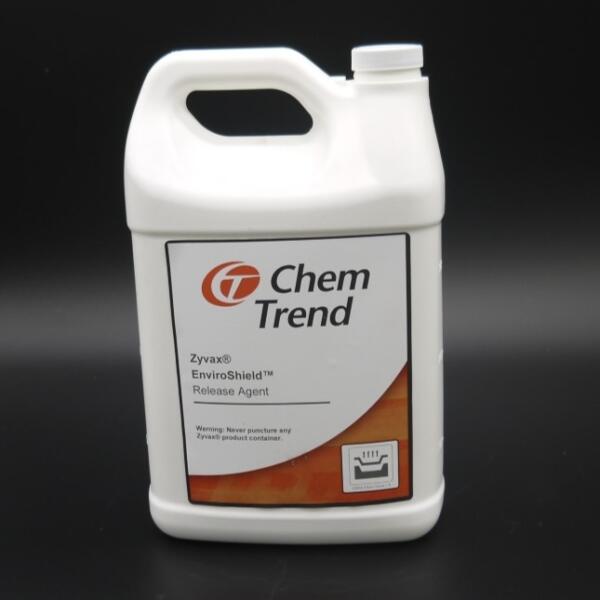

- Mold release agents for composites

Composite release agents ensure that these parts can be removed easily from their molds and that molds aren’t damaged by unwanted adhesion during the production process, while

Release Agents, Additives & Ancillaries

Haufler Composites provides carbon fibres and fabrics, glass fibers and fabrics, peel ply, release agents, carbon fiber reinforced sheets and more. Home +49 (0) 7344 924 997-0

High release performance and multiple demoulding with easy application as well as good wetting of the release film and an easy postprocessing of part surfaces are the most frequently asked requirements in the composite area. ACMOS

Our classic mould release agents are multi-purpose, liquid, solvent-based and silicone-free external products with short drying times. The use of these products eliminates the need for repeated waxing and polishing, as a single application

Miller-Stephenson High Temperature Release Agents offers efficient and effective release solutions for molding operations which operate at temperatures exceeding 1562 °F / 842°C,

Release agents for composites; Release agents for rotational molding; Polyurethane mold release agents; OTHERS. Silicone oil; Epoxy Resin; BLOG; Release agents. Twitter Share Pin

Composite release agents ensure that these parts can be removed easily from their molds and that molds aren’t damaged by unwanted adhesion during the production process, while

Epoxy Mold Release Agents

Composite release agents ensure that these parts can be removed easily from their molds and that molds aren’t damaged by unwanted adhesion during the production process, while

All-purpose release agent. Facilitates difficult releases at temperatures of 110 °C – 260°C without discolouration and other undesiered effects on curing etc. Durable release film; Levels over

- High Temperature Release Agents

- Release Agents, Additives & Ancillaries

- CR1 Easy-Lease Chemical Release Agent

- Internal Release Agents for Composites

R&G Faserverbundwerkstoffe GmbH Im Meißel 7 – 13 Bonholzstr. 17 71111 Waldenbuch • Germany Phone: +49 (0)7157 / 530 46 – 0 E-mail: [email protected]

Use CR1 Easy-Lease to prevent moulds sticking to patterns and components sticking to moulds. Compatible with nearly all tool surfaces, cure temperatures and resin systems including epoxy,

McLube® offers mold sealers, external release agents, and cleaners tailored to aerospace, automotive, marine, construction, and recreational composites manufacturing.

Composite mold release agents are formulated to protect mold surfaces from highly abrasive resin compounds. In the composite industry, the cost of tooling is particularly high, hence the

Mold release agents for composites

Release agents and process chemical specialties can do more than help make for a smooth manufacturing process. They are capable of elevating the entire composites industry. From the

Carbon/epoxy composite mould with release agent (Marbocote Spraycote) being spray applied. However, concern for environmental safety, as well as increasing regulation,

We offer an additive, that has been developed and optimized to be used in combination with the semi-permanent release agents from the Mikon® series. The combination results in an improved processability and improved surface

Ideal for high performance composite structures and large scale molding operations, ReleaSys 8800 excels at releasing composite parts from complex, intricate mold geometries. ReleaSys

Marbocote Ltd continues to advance release agent technology, delivering durable release coatings that ensure maximum productivity. Contact Marbocote Learn more. Continued

A range of high quality mould release waxes and release agents to facilitate easy and reliable release of cured composite parts from the pattern or mould. In stock, buy online.

In composite manufacturing, release agents are used to reduce the adhesion of resins to molds or release films and allow easier demolding of composites. Choosing the right release agent

Internal release agents usually consist of an additive mixture in solid or liquid form, which is premixed in the resin during the manufacturing process and increase the function of external

Release agents are an integral part of many manufacturing processes. Specialty mold release agents can help you enhance productivity, extend tool/die/mold life, increase cycle times, improve part/surface quality, and reduce scrap and

Composite release agents ensure that these parts can be removed easily from their molds and that molds aren’t damaged by unwanted adhesion during the production process, while

We offer a good range of release agents: poly vinyl alchohol, waxe and semi-permanent release agents. Semi-permanent mould release technology has provided industries with an alternative

Our complete range for the composites industry includes a great variety of sealers, external and internal release agents, additives and cleaners. Not only small and medium-sized businesses

- Ihs Holding Limited: Economic Crisis Brings Opportunity

- El Gobierno Y Los Principios De La Democracia

- Gummibekleidung Latex

- Анисимова, Наталья Юрьевна — Википедия

- Key Numbers To Know From 2024-22 Season

- Find Used Porsche 911 Series In Herne

- Victoria Swarovski Begeistert Mit „Mosaik-Kleid“

- Telefonbuch Stockach _ Telefonbuch Stockach Bodensee

- Anestesia Peridural : Para Que Serve, Riscos E Efeitos

- Grundschule Lübz | Grundschule Lübz Schützenstraße

- Erkenntnisse Aus Der Jlu-Forschung Zum Coronavirus — Jlu

- Dübendorf / Eglishölzli Karte

- Comic Und Manga Convention

- Top 9 Gebäudereinigung Zehdenick