Mrp System: How To Calculate Material Requirements?

Di: Everly

Material Requirements Planning (MRP) is a system designed to calculate the raw materials needed and schedule production processes efficiently. MRP helps in creating a detailed production plan to ensure material availability

Material Requirements Planning Excel Template Generator

Manufacturing companies can make a best use of the MRP template by simply creating charts and tables for calculating the materials needed to manufacture any item. The raw materials

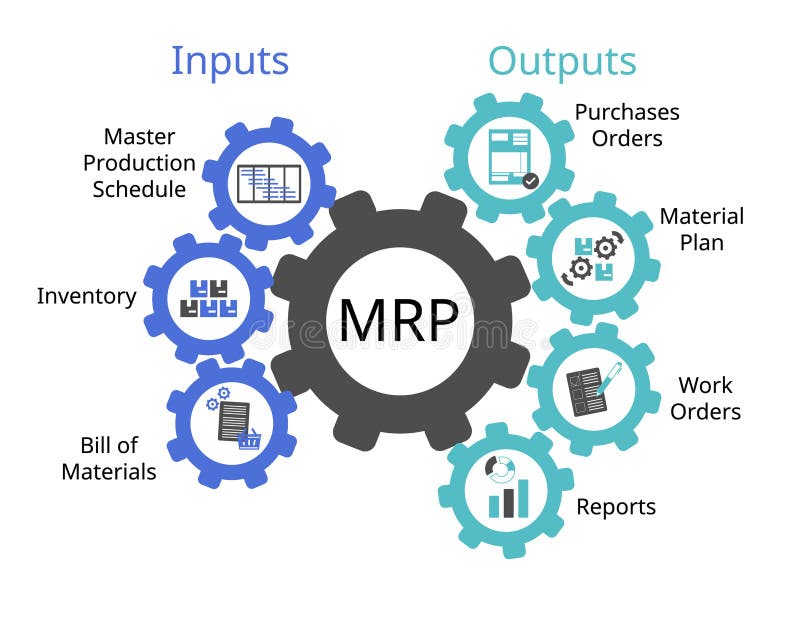

The MRP system uses sales forecasts, current inventory levels, bills of materials, and the master production schedule to calculate material requirements and generate purchase orders to suppliers at the right time. Here

Manufacturers use MRP systems to calculate what materials they’ll need, in what quantities, and when materials should arrive to meet production needs. MRP systems integrate data from several sources—demand, bills of

Each structure in the Bill of Materials system is processed to calculate the low level codes. This information is used during the netting-off phase to ensure that top level items are processed

An **MRP** system functions by analyzing the **Master Production Schedule** and **Bills of Materials** to calculate material requirements for production. The analysis

- Build a Material Planning Tool in 10 Minutes

- What is Material Requirements Planning ?

- A Close Look at Material Requirement Planning and MRP System

How to use material requirements planning Here’s how to use a material requirements planning system: 1. Identify production requirements The first step in using an

What Is MRP? 2025 Material Requirements Planning Guide

How material requirements planning (MRP) systems work. High-level MRP systems work by analyzing several aspects of the manufacturing process, such as demand forecasts,

When introduced in the 1960s, material requirements planning (MRP) was the “killer app,” triggering widespread adoption of business software and the computers needed to run it.

Material Requirements Planning (MRP) is a powerful tool that helps manufacturers manage their inventory and production processes. In this comprehensive guide,

Material requirements planning (MRP) balances supply and demand for purchased and manufactured items. Given a set of demands or requirements, MRP automatically calculates a

- MRP Systems: Process, Benefits, Types & Examples

- Material requirements planning

- What Is Material Requirements Planning ?

- What is MRP?, A Comprehensive Guide with 100% Examples on Material

- MRP: how material requirements planning works?

Material Requirements Planning (MRP) methodology stands as a cornerstone in achieving these objectives, facilitating seamless operations by ensuring the right materials are available at the right

Material Requirements Planning Excel Template. A Material Requirements Planning (MRP) Excel template is a structured spreadsheet tool for managing production inventory and scheduling

First, the method enables you to calculate gross requirements (using the bill of materials), then net requirements (using stocks and work-in-progress). Calculation of capacity

Material Requirements Planning (MRP) is a powerful tool that helps manufacturers manage their inventory and production processes. MRP uses forecasting, bill of

At its core, MRP is a systematic approach to inventory management and production scheduling. It involves the use of computer-based systems to calculate the materials needed for production

MRP systems analyze factors such as production schedules, lead times, inventory levels, and demand forecasts. They use this information to generate accurate

Ideally, your manufacturing software performs several MRP calculations to optimize your inventory quantities to match incoming orders. MRP or materials requirements planning refers specifically to determining how much material

To run an effective Material Requirements Planning, an ERP system requires several critical data parameters: A detailed list of all components, materials, and parts required

We can summarise how an MRP system works by defining the calculations needed to be performed. These are assembled here into 5 steps: Gross first-level component requirements

We can break down how an MRP system works into four comprehensive steps: Estimate Required Materials: Use the master production schedule to gauge product demand

What Is Material Requirement Planning (MRP)? Material requirement planning (MRP) is a systematic approach to managing all resources in a manufacturing process.

MRP uses information from the bill of materials (BOM), inventory data and the master production schedule to calculate the required materials and when they will be needed in the manufacturing process.

Material Requirements Planning (MRP) is a production management system that determines the quantities of materials needed to meet production demands and plans their procurement. By

Every manufacturer must plan for the delivery, inventory, utilization, and disposition of materials to run an efficient operation. That’s MRP, or materials requirements

MRP is a planning tool that helps manufacturers calculate the materials needed for production based on the production schedule and inventory levels. It considers factors like lead

Material Requirements Planning (MRP) systems are pivotal in the manufacturing industry, providing a structured approach to production planning, inventory management, and

By incorporating factors like lead times, inventory levels, and customer orders, an MRP system calculates the exact quantity of raw materials and components needed to meet

Material Requirements Planning (MRP) is an essential tool for operations professionals seeking to optimize inventory and production processes. This comprehensive guide covers various aspects of MRP, including its

The MRP calculation process involves three main steps: determining the demand for the finished product, calculating the net requirements for each component, and determining the order quantities and timing for each

- Qual É A Diferença Entre O Windows De 32 Bits E 64 Bits?

- Installer Acer Crystal Eye Webcam [Résolu]

- Qhboxplotmodelmapper Class

- Fußchirurgie Balg Baden – Krankenhaus Mittelbaden Fußchirurgie

- La Hora Zanahoria

- Vodafone Secure Net Im App Store

- Flugzeit Nach Dublin _ Welcher Flughafen Fliegt Dublin An

- Proxxon Schleif Zubehör Online Kaufen

- Muchas Formas De Reafirmar La Piel Flácida Del Cuello

- Übel Blatt Teaser Visual: Übel Blatt Anime Deutsch