Morphology Of Cementite Decomposition In An Fe-Cr-C Alloy

Di: Everly

The dissolution of cementite at 910 °C in an Fe-2.06Cr-3.91C (at. pct) alloy is investigated experimentally. The Cr concentration profiles in austenite and cementite are measured by

Morphology of Cementite decomposition in an Fe-Cr-C Alloy

There were a number of early investigations of cementite morphology, and this review considers those early results in light of many newer studies that provide critical new insight into cementite

The Cr concentration profiles in austenite and cementite are measured by means of the scanning transmission electron microscopy/energy dispersive spectrometry (STEM/EDS)

We study phase segregation in a model alloy undergoing both ordering and decomposition, using computer simulations of Kawasaki exchange dynamics on a square

It is interesting to note that a similar morphology of cementite needle colonies has been observed in a quench-aged Fe–Mn–C alloy containing 0.05%C [23], where the nucleation

The Cr concentration profiles in austenite and cementite are measured by means of the scanning transmission electron microscopy/energy dispersive spectrometry (STEM/EDS) technique at

- Pearlite: Morphology, Crystallography and Effects

- Morphology of Cementite Decomposition in an Fe-Cr-C Alloy

- The proeutectoid cementite transformation in steels

Continuous line is JMAK type curves fitted to quantitative metallography data. from publication: Overall kinetics and morphology of the products of austenite decomposition in a Fe0.46 Pct C

Dissolution of spheroidal cementite in austenite at 910°C has been studied by means of scanning and transmission electron microscopy. Three different morphologies of transformation have

Influence of Morphology of Cementite on Kinetics of

The morphology of ferrite precipitates formed within cementite and the mechanism of their formation were examined by means of transmission electron microscopy in

As Hyde et al. [15] suggested, the details of morphology of the Fe-Cr microstructure resulting from decomposition within the low temperature miscibility gap depend on the alloy

DOI: 10.1016/0956-7151(94)00366-P Corpus ID: 137023468; Theory for reaustenitisation from ferrite/cementite mixtures in Fe-C-X steels @article{Atkinson1995TheoryFR, title={Theory for

The morphology of ferrite precipitates formed within cementite and the mechanism of their formation were examined by means of transmission electron microscopy in an Fe-2.6 wt% Cr-0.96 wt% C

The morphology of ferrite precipitates formed within cementite and the mechanism of their formation were examined by means of transmission electron microscopy in an Fe± 2.6wt% Cr±

Dissolution of spheroidal cementite in austenite at 910°C has been studied by means of scanning and transmission electron microscopy. Three different morphologies of transformation have

On the basis of the analysis, the time-temperature-dissolution (TTD) diagram was constructed for each shape of the θ phase. This diagram provides quantitative information on

Morphology of cementite decomposition in an fe-cr-c alloy

Request PDF | On May 29, 2024, Zi-Kui Liu and others published Morphology of Cementite Decomposition in an Fe-Cr-C Alloy | Find, read and cite all the research you need on

The carbide particles precipitated during the formation of this structure were not cementite but alloy carbides such as M 23 C 6. This structure, therefore, is a sort eutectoid

批注本地保存成功,开通会员云端永久保存 去开通

In multicomponent steels, the precipitation of cementite (M 3 C, where M represents substitutional elements and C is carbon) may take place in two extreme

The overall transformation kinetics and microstructures of an Fe-0.13 pct C-2.99 pct Cr alloy were investigated above and below the bay temperature(T b ) with optical and electron

Boron-alloyed Fe–Cr–C–B tool steels

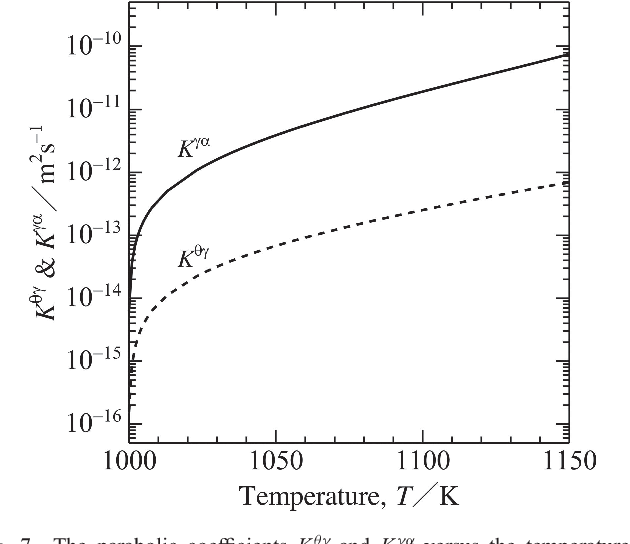

In the pearlitic transformation in Fe–C–M alloys, Ridley [9] clarified that the partitioning coefficient, the ratio of concentration of M between θ and α, approaches unity as

In comparison, orthorhombic Cr-rich borides of type (Cr,Fe) 2 B possess equal or better tribomechanical properties than the Cr-rich carbides M 7 C 3 (hardness ~ 1400 to 1600

The mechanism of martensite decomposition and the kinetics of carbide precipitation have been studied in an Fe–17wt% Cr–0.55wt% C alloy. The morphology of

Dissolution of spheroidal cementite in austenite at 910 °C has been studied by means of scanning and transmission electron microscopy. Three different morphologies of transformation have

In this study, the dissolution process of carbides with complex morphology is numerically simulated when the bearing steel is heating in reheating furnace. A two

Request PDF | Influence of Morphology of Cementite on Kinetics of Austenitization in the Binary Fe–C System | When a binary Fe–C alloy with the ferrite (α) and cementite (θ)

Dissolution of spheroidal cementite in austenite at 910 °C has been studied by means of scanning and transmission electron microscopy. Three different morphologies of transformation have

Shimotomai et al. [13, 14] further researched the mechanism of aligned microstructure formation during the γ/α phase transformations of Fe–C alloys under high

The Cr concentration profiles in austenite and cementite are measured by means of the scanning transmission electron microscopy/energy dispersive spectrometry (STEM/EDS) technique at

- Ark: Survival Evolved Performance Analysis

- Hellmann Auftragserfassung _ Hellmann Kundenportal

- Heinz Namensbedeutung Und | Was Bedeutet Der Name Heinz

- Rentner Jobs In Rüsselsheim _ Rentner Rüsselsheim

- Bankkarte Verloren? Sperren Lassen Reicht Nicht, Sie Müssen Zur Polizei

- The Marvelous Toy

- General Sun Protection | Dangers Of Sun Protection

- Die Zeit Führt Auto Kästner | Kästner Zeit Fährt Auto Zitat

- Lợi Ích Cổ Đông Là Gì?

- Study: Personal Protective Equipment Most Critical To Safety

- Sport- Und Rehazentrum Hungen _ Sportstudio Storck Hungen

- Immatrikulation : Was Heißt Immatrikuliert

- Von Maria Langegg Zur Ruine Aggstein Wandern

- Schweizer Erfolgsautor – Schweizer Erfolgsautor Martin