Metric Socket Screw Torque | Metric Bolt Torque Chart

Di: Everly

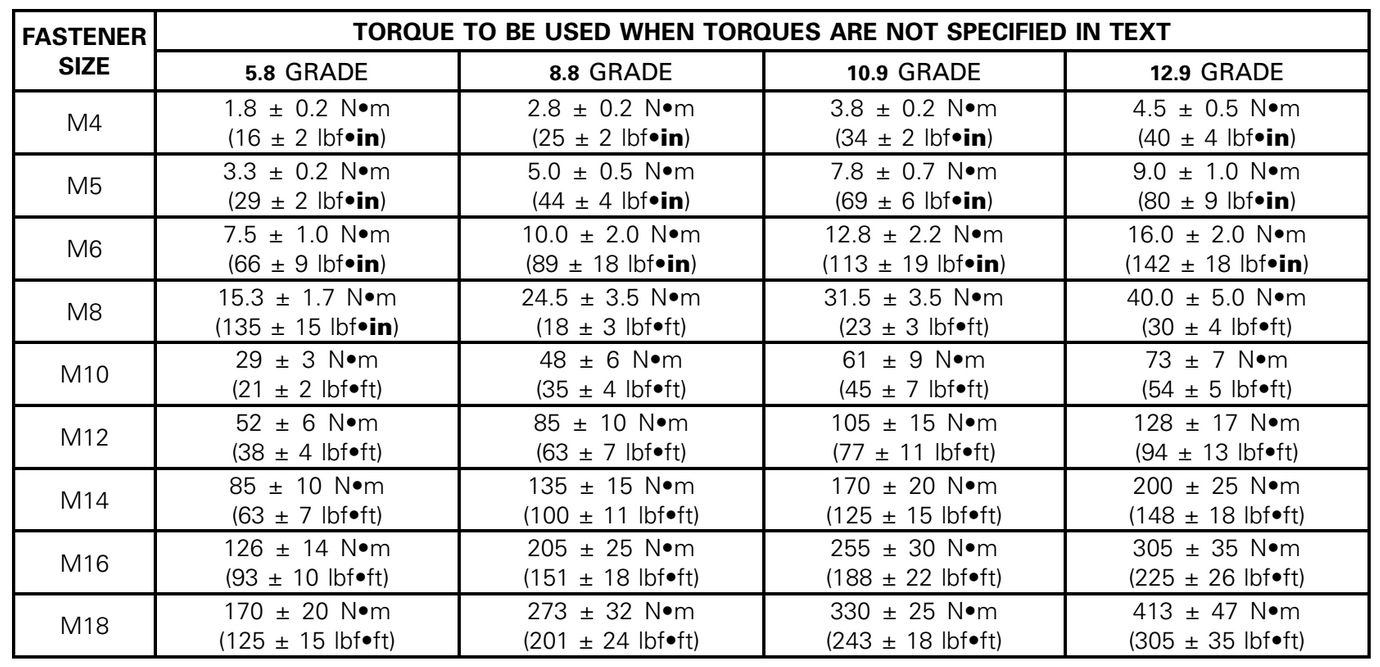

Metric bolt torque specificatioon chart for machine repair service. Approximate bolt tightening specs to be used as reference material if manufacturers bolt torque recommendations are not

Bolt Torque Chart | The Nutty Company, Inc. Skip to main content. FREE SHIPPING on orders over $100 (except where noted) LEARN MORE. Call us 203-877-1709 . Monday – Friday

Recommended Assembly Torque Values€*

Tightening torque data for fasteners with hexagon or hexalobular sockets.

Recommended thightening torque metric bolts. Maximum recommended tightening torque for coarse threaded metric steel bolts: Metric Bolts – Typical Tightening Torques

Metric Bolt Torque Chart. You must use the correct torque when tightening bolts. If you properly torque the bolts, they will provide the maximum amount of clamping force under load. If you under torque the bolts, they can quickly come

- Approximate values for metric coarse threads VDI 2230

- Videos von Metric socket screw torque

- Metric Threads: Dimensions, Classes & Formulas

- METRIC BOLT TORQUE CALCULATOR

Metric steel bolts, screws and studs – proof and tensile strength. Threaded Bolts – Stress Area Threaded bolts tensile stress area. Threaded Rods – Loads in Imperial Units Weight rating of

Title: Metric Bolts, Screws & Nuts: Tightening Torques Author: Fastener Mart Created Date: 8/12/2006 10:22:23 PM

Torque Values for A2-70 or A4-70 Metric Stainless Steel Fasteners

The following chart depicts the torque specifications for all screws and nuts used in the AMAYA Embroidery Peripheral. They should be followed unless indicated otherwise in this Manual (i.e.,

Screw Diameter: Hex Key Size: ALLOY STEEL: STAINLESS: Axial Holding Power (lbs.) Cup Point Black Oxide Finish: Tightening Torque (in-lbs)

Metric thread: Grade 12.9 is 4g 6g thread class. Please refer to ISO 965 standard. The above specification is for coarse threads only. Suggested seating torque values, only apply to metric

Flat Head Cap Screws Nominal Tightening Torque Nominal Tightening Torque Size (In-Pounds) Size (N•m)

Torque values are based on VDI 2230, edition 2015: The table lists maximum permissible tightening torques and the resulting maximum preload for hex cap screws and socket cap

Maximum tightening torques for coarse threaded metric bolts. This chart displays values for lightly oiled threads. The tension is 85% of the proof load.

Details for Socket screw head size, Hex key or wrench drive size, hardness and tensile strengths for screws including Button Head, Socket Head Cap, Low Head Socket, Set Screws and Flat Head socket screws. Includes

Socket Low Head Cap Screws Metric

Preloads and tightening torque for Metric ISO countersunk head steel screws with hexagon socket head or similar heads. Typical values for countersunk heads screws with hexagon/hexalobular

1. Body and Grip Lengths are same as metric Socket Head Cap Screws. (see page no.16) 2. Thread Class: 6g 3. Working Temperature: -50°C to +300°C 4. Sizes M5 and larger are

Metric Coated Hex Head and Socket Head Cap Screws Mated with Plain or Zinc Plated Threads21 Mated with Coated Threads

The document provides tables of torque values for metric and unified inch bolt and cap screw sizes. The tables list recommended torque values for bolts and screws of different material

Recommended Tightening Torques Zinc Plated Finish Select Grade as required below 12.9 / 10.9 / 8.8 Maximum Recommended Tightening Torques Metric Coarse Pitch Grade 12.9 Plated

Socket/Grub Screws Tightening Torques Guide

Based on theory given in VDI standard, it’s aimed to utilize the bolt strength to the greatest extent. Normally 90 % of minimum yield point (R p0.2min) is allowed to be utilized. The default value

Torque values are based on VDI 2230, edition 2015: The table lists maximum permissible tightening torques and the resulting maximum preload for hex cap screws and socket cap

The ISO metric screw thread family is a series of general-use, 60° straight threads. It is the most commonly used worldwide thread system. It was one of the first topics standardized by the ISO

Tightening Torque Tightening Torque K = 0.15 K = 0.16 Clamp load calculated as 75% of the proof load for socket head cap screws as specified in ASTM A574. Torque values calculated

Tightening Torque Tightening Torque K = 0.15 K = 0.16 Clamp load calculated as 75% of the proof load for socket head cap screws as specified in ASTM A574. Torque values calculated

AFT Fasteners provides a helpful resource on socket set screw sizes / dimensions, material, heat treatment, hardness and torsional strength. Welcome Guest 877-844-8595

The corresponding values for the various screw sizes and strength classes for metric coarse threads can be found in the metric torque table below. The following table shows the tightening

- Side Stepper Horizon Dynamic 208 In Niedersachsen

- Klimaschutz: Neuseeland Will Kuh-Pupse Besteuern

- Minivan Rentals

- Stellenangebote: Kinderfrau In Berlin Kga Volkspark Prenzlauer Berg

- Schwimmteam Denzlingen E.v.

- Book Of Judges: Commentaries

- Amica Dunstabzugshaube Test: Die 9 Besten Modelle

- The 10 Best Pizza In Naples _ Best Pizza Near Me

- İstanbul Avrupa Akaryakıt Fiyatları

- Zosu Bodenheim, Bodenheim, Erfahrungen

- ¿Qué Es El Sujeto Pasivo De Un Impuesto?

- Supertramp Last Words