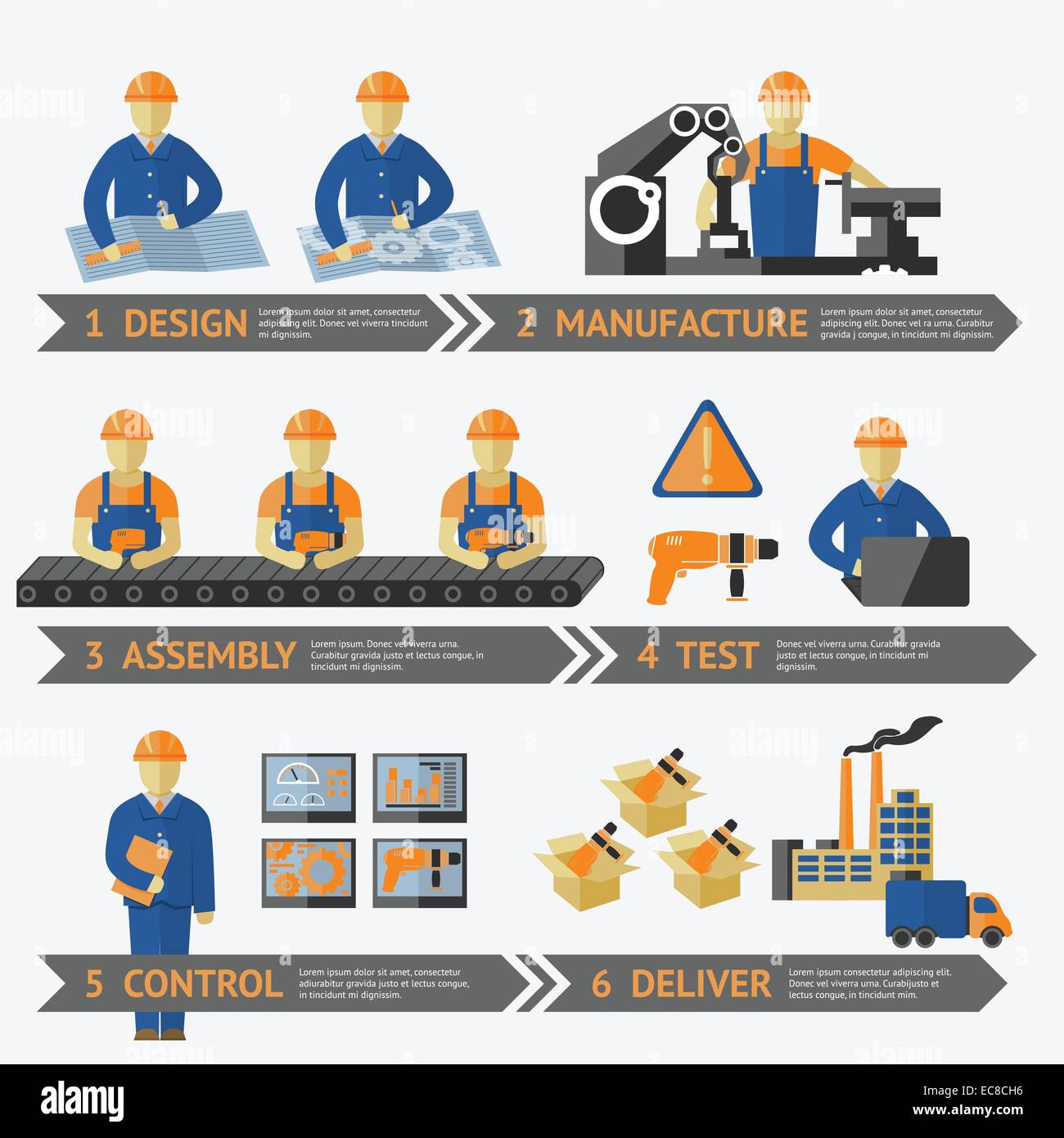

Manufacturing Design Process: Design For Manufacturing Dfm

Di: Everly

Simplify Manufacturing Processes: Designs should leverage processes that are efficient and repeatable, such as minimizing complex machining operations or favoring injection molding

7 Additive Manufacturing types

Extend the powerful tools you already know into factory design and construction. We’ve made it easy to use the core 2D, 3D, and data management tools included in the

Design for Manufacturing is a comprehensive approach to product design that takes into account the manufacturing process from the very beginning. By considering production

1.2.1. Develop a Systematic Design Methodology for Manufacturing Processes The primary goal of this research was to develop an objective driven methodology for manufacturing process

- Your Ultimate Guide to Design for Manufacturing

- Videos von Manufacturing design process

- Metallic Additive Manufacturing: Design, Process, and Post

- What is Design for Manufacturing and Assembly?

Consider Manufacturing Processes: Designing with specific manufacturing processes in mind can lead to more efficient production. This involves understanding the capabilities and limitations of

This book is a comprehensive guide to Additive Manufacturing (AM) product development. It offers a practical, reader-friendly approach to integrating the stages of product development. It covers

PCB Manufacturing Process

Design for manufacturing (DFM) is a crucial process that ensures designs are optimized for efficient and cost-effective manufacturing. By integrating manufacturing considerations early in

Every manufacturing process—be it injection molding, CNC machining, or additive manufacturing—has its own set of guidelines for optimal design. For example, consider factors like wall thickness, draft angles, and gate locations if you are

Apart from several benefits of WAM processes, it is still far behind conventional manufacturing processes in terms of manufacturing time and cost. Furthermore,

Learn how Design for Manufacturing (DFM) can optimize your product’s manufacturability, reduce costs and improve quality in this comprehensive guide.

Manufacturing engineering is a branch of engineering that focuses on the design, analysis, development, and improvement of manufacturing processes to efficiently produce

Incorporating Design for Manufacturing (DFM) into the product development cycle offers multiple benefits, including reduced costs through simplified manufacturing processes

When engineers and designers work together, it becomes easier for them to spot problems early on in the manufacturing process. They can share notifications with one another

Design for Manufacturing: Unveiling Efficiency and Innovation in Product Development. Design for Manufacturing (DFM) is a strategic approach that integrates product design and manufacturing

If anyone wants to understand in-depth about manufacturing design, one must have profound knowledge in the fields of material science, mechanical engineering design,

- Engineering 101: Design for Manufacturing

- PCB Manufacturing Process

- Design for Manufacturing: DFM Principles and Best Practices

- Additive Manufacturing: Design, Processes and Applications

250136 Contract for the Design, Manufacture, Supply, Delivery, Installation and Maintenance of an Agile Multifunctional Composite Automation cell. Queen’s University Belfast

Design for Manufacturing (DFM), also known as Design for Manufacturability, is a comprehensive approach to product design that focuses on optimizing the manufacturing process from the earliest stages of development.

Define what DFMA is and why it is important for the design process. Apply DFMA principles and practices in different domains and contexts. Describe methods and tools are available for

What is Design for Manufacturing (DFM)? It is the process of designing products, parts, or components to simplify the manufacturing stage. Engineers or designers optimize each feature and element to ensure the

Manufacturing Process Design and Optimization, Robert F. Rhyder 51. Statistical Process Control in Manufacturing Practice, Fred W. Kear 52. Measurement of Geometric Tolerances in

Design for manufacturing (DFM) is a process that can help you streamline your production processes and improve your bottom line. It plays a crucial role in ensuring that

We just reviewed how to plan and design a manufacturing plant layout. Now, you should know the benefits and process that goes into making a layout for your plant. With Visual

Design for Manufacturing (DFM) is the process of designing parts, components or products for ease of manufacturing to make a better product at a lower cost. This is done by

Design for Manufacturing (DFM) describes the process of engaging engineers to optimize a product or a design element to ensure it can be manufactured as easily, cost-effectively, and

Designing for Manufacturing and Assembly (DFM or DFMA) is a critical part of the product development cycle. It involves optimizing the design of your product for its manufacturing and

Additive Manufacturing: Design, Processes and Applications. SpringerBriefs in Applied Sciences and Technology. SpringerBriefs present concise summaries of cutting-edge research and

The output of the manufacturing process design is a comprehensive plan and outlines how the product is produced efficiently and effectively. Skip to content. PRETESH

Design for manufacturing (DFM) improves efficiency by addressing assembly, testing, and factory constraints early, aligning R&D, and manufacturing teams.

• Sequential Process – Design ->Manufacturing – Waste resource, waste time • Concurrent Process – All disciplines are involved in the earliest stages of product design – Progress

- Анисимова, Наталья Юрьевна — Википедия

- La Mention De La Date De Naissance Sur Le Cv : Un Dilemme Actuel

- Cohesion : Définition De Cohesion

- Bodos Bücher Kommen Nach Bochum

- Perfectcar Köln Telefonnummer

- Heil-Und-Sohn-Goettingen In Bad Gandersheim

- Speisekarte Von La Esquina Restaurant, Cham

- Reifenmontiermaschine Test _ Reifenmontiermaschine Für Kleine Reifen

- Ramazanın Kaçıncı Günündeyiz 4 Nisan 2024? Ramazanın

- Bedeutung Von Keine Wärme Von Kaisa

- Mejor Hora Para Inyectar Insulina

- Alchemy Explained In 5 Minutes

- Wetter Hondelage – Wetter Hondelage 14 Tage

- Lower Airway Disease