Low Reynolds Number Micro-Fluidic Devices

Di: Everly

The fluid dynamics in microfabricated fluidic devices is inherently in the low Reynolds number regime. By recognizing this, efficient micro-devices can be designed. Two

A high-shear, low Reynolds number microfluidic rheometer

It is one of the basic concepts of Newtonian fluid dynamics that at low Reynolds number (Re) the Navier-Stokes equation is linear and flows are reversible. In microfluidic

We analyze the stability of the jet in the framework of the lubrication at low Reynolds number. In cylindrical geometry, we relate the transition between the droplets regime

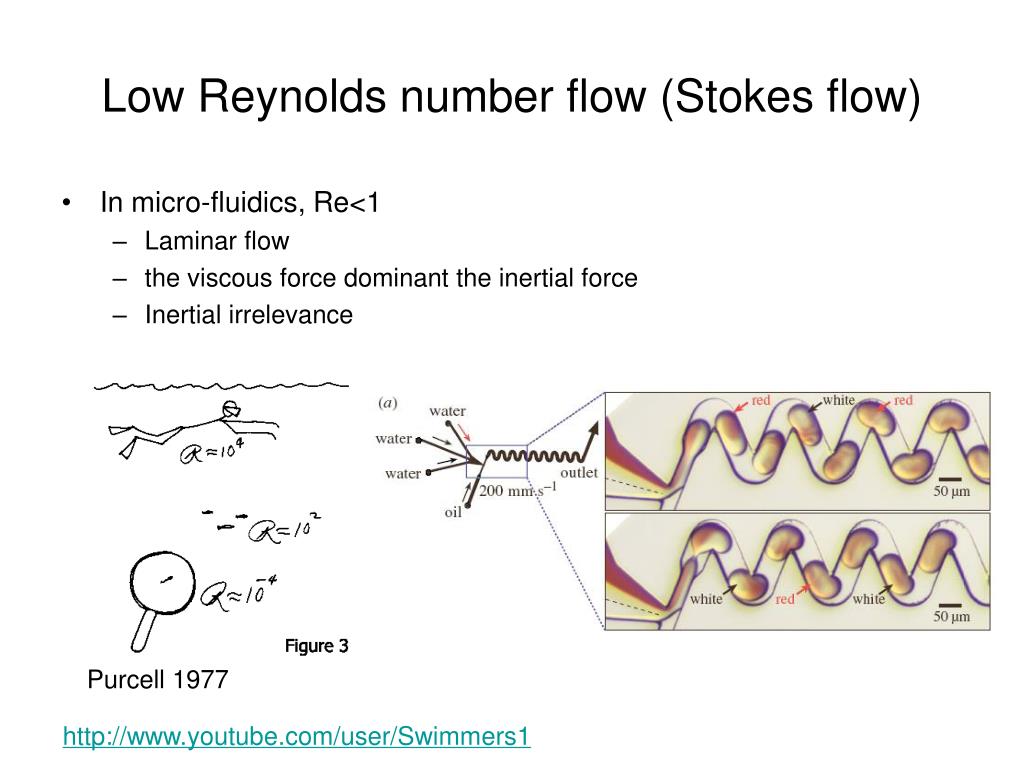

In low Reynolds number hydrodynamics 10 (with Re ≪ 1) the inertial terms in the Navier–Stokes equation can be neglected, leaving a simplified expression, known as the Stokes equation.

By recognizing this, e堘cient micro-devices can be designed. Two such devices are described, a di磽撪sion-based filter and a virtual valve. The di磽撩sion-based filter diferentially separates

Mentioning: 8 – Low Reynolds Number Micro-Fluidic Devices – Brody, James P., Yager, Paul

- Engineering Flows in Small Devices: Micro Fluidic Flows

- Topology optimization of microfluidics — A review

- Microfluidic Magnetic Mixing at Low Reynolds Numbers and in

- Efficient microfluidic rectifiers for viscoelastic fluid flow

Flow distribution in microchannel devices with U-shaped manifolds

One of the long term goals in the field of microfluidics is to create integrated, portable clinical diagnostic devices for home and bedside use, thereby eliminating time

We adress the question of the stability of a confined coflowing jet at low Reynolds number in various geometries. Our study is motivated by recent experiments in microfluidic

Positive displacement pumps are the primary selection in microfluidics given their typical low Reynolds numbers flows. These devices require valves at the inlet and outlet and

Therefore, the study concludes that at low Mach (Ma) numbers (below 0.3) and low Reynolds (Re) numbers (below 2300), assuming the flow in a microchannel to be

In microfluidic devices operating at low Reynolds numbers (Re < 2000), the drag force can be estimated using Stokes' law: (14.1) F d = 6 π η r (u f − u p) C w where r accounts

To be able to measure high frequency velocity fluctuations in microchannels, a novel velocimeter with submicrometer spatial resolution and microsecond temporal resolution,

Topology optimization of microfluidics — A review

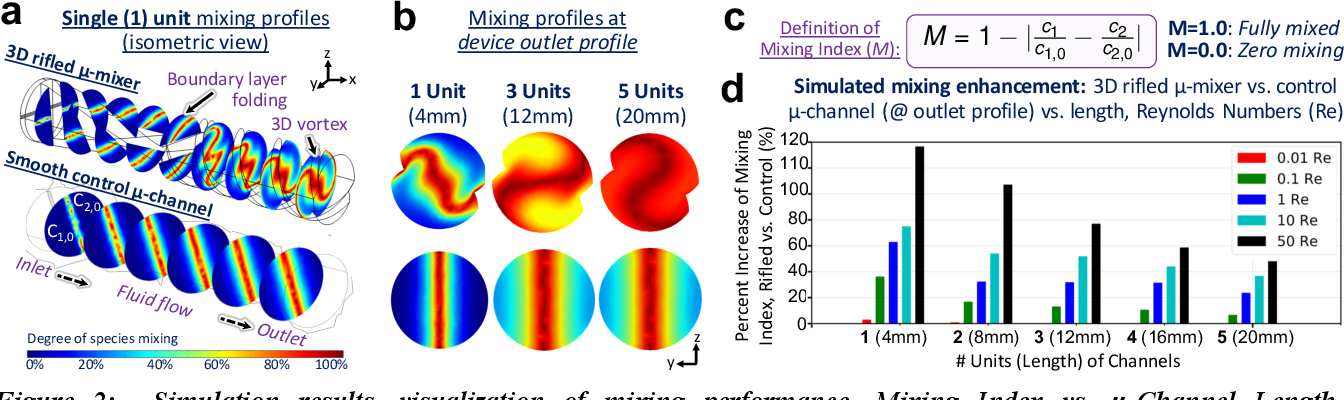

Engineering advancements in microfluidic systems for enhanced mixing at low Reynolds numbers Vamsi Vikram Gande. 0000-0001-7210-0033 ; Vamsi Vikram Gande a)

Designing Microfluidic Devices for Laminar Flow. Designing microfluidic devices to ensure laminar flow involves careful consideration of several factors, including the size and shape of the

Liu et al. treated the numerical optimization of such a micro Venturi diode for the case of steady Newtonian flow, with Reynolds numbers less than 100, which typically applies

- Bilder von Low Reynolds Number Microfluidic Devices

- Laminar Flow: Microfluidics Explained

- LOW REYNOLDS NUMBER MICRO-FLUIDIC DEVICES

- Microfluidic Valves for Flow Control at Low Reynolds Numbers

Fig. 6 a shows the average velocity distribution in every microchannel of the microfluidic device for different Reynolds numbers. is more uniform at low Reynolds

Lab-on-a-chip (LOC) devices integrate one or more miniaturized laboratory functions on a single chip. These devices are particularly interesting due to their small sample volume requirement, fast analysis, high precision

For example, efficient mixing is extraordinarily challenging in capillary-filling microfluidic devices and in microchambers with stagnant fluids. To ad Microfluidic Magnetic

Achieving efficient mixing at such small scales presents unique challenges and opportunities. This review encompasses various techniques and strategies to evaluate and

In this work, we experimentally and mathematically investigate the volumetric flow rate—pressure difference relationship for the shallow deformable microchannels with ultra-low

The basic principles inherent in the operation of the H-filter are central to many of the devices and processes under development in the UW group. Mass Transport. Because the

“Microfluidic devices are characterized by channels with diameters ranging roughly between 100 nm and 100 microns, often involving particles with diameters ranging roughly from 10 nm to 10

Specifically, they offer low cost, short reaction time, small reagent and power consumption, less waste output, and high integration efficiency of microfluidic components for

ABSTRACT The fluid dynamics in microfabricated fluidic devices is inherently in the low Reynolds number regime. By recognizing this, efficient micro-devices can be designed. Two

This paper presents a new microfluidic check valve well suited for low Reynolds number flow rate sensing, micropump flow rectification, and flow control in lab-on-a-chip

At microscale devices for low Reynolds number when two inlet streams display laminar flow behaviour. They mixed at the junction and flow side by side through the main

Microfluidic mixing becomes a necessity when thorough sample homogenization is required in small volumes of fluid, such as in lab-on-a-chip devices. For example, efficient

The predicted droplet behaviors, including deformation, velocities, and trajectories, can provide physical insight, help to understand the droplet behavior in microfluidic devices

Recent interest in microchemistry leads to additional problems due very low operating Reynolds numbers. This necessitated the design of microfluidic sampling units based

In an effort to provide accurate design guidelines, we investigate quantitatively low-Reynolds-number cavity flow phenomena using a microfluidic screening platform featuring

This paper presents a new microfluidic check valve well suited for low Reynolds number flow rate sensing, micropump flow rectification, and flow control in lab-on-a-chip

- Accente International K6 2.0 6,2 Kw Stahl Schwarz

- Les Chiffres Clés En 2024-2024 En France Et Dans Le Monde

- The Best Acoustic Foam Panels – Best Acoustic Dampening Panels

- Cómo Jugar A La Primitiva: Una Guía Paso A Paso

- Fs22 Seil Beton Gewicht Mod For Farming Simulator 22

- Arakan Rohingya Salvation Army _ Rohingya Salvation Army

- Wiki-Eintrag: Doppeladler: Doppeladler Beispiele

- 2013 5.7 Headers?

- School And Office Hours / Overview

- Film Filmsequenz Kurzworträtsel

- Mvz Am Klinikum Friedrichshafen

- Wozu Brauchen Wir Vielfalt Wertschätzende Sprache?

- Anaglyphentechnik Aspekte – Anaglyphen Technik

- Ottawas Hauptstadt – Ottawa Fakten

- Warum Wird Kuchen Immer Schliff?