Laser Energy Density Dependence Of Performance In Additive

Di: Everly

In the present study, AlCoCrFeNi2.1 eutectic high-entropy alloy (EHEA) has been fabricated by laser melting deposition (LMD). The influence of laser energy density on

Effect of laser beam energy density distribution on the main properties

In this paper, the control of the Gaussian laser beam energy density distribution characteristics is realized by controlling the defocus amount. The influence of the energy

Laser additive manufacturing of metal components could be divided into powder bed systems such as selective lase sintering (SLS), selective laser melting (SLM) or powder

Figure 2 indicates a strong relationship between the relative density and laser input energy density. As the scan speed decreases, the laser energy density increases, which results in increased relative density, with the highest

- Laser Energy Density Dependence of Performance

- Effect of Laser Energy Density on Microstructures and Properties of

- 激光能量密度对金属增材制造微观结构 及力学性能的影响研究

- Effect of laser beam energy density distribution on the main properties

Because material anisotropy significantly influences the comprehensive performance of SLM parts, some studies have been conducted to reveal this phenomenon in

In the present study, AlCoCrFeNi2.1 eutectic high-entropy alloy (EHEA) has been fabricated by laser melting deposition (LMD). The influence of laser energy density on microstructures, wear

Effect of Laser Energy Density on Microstructures and Properties of

In particular, laser additive manufacturing (LAM), a type among AM technologies, enables the creation of microscale features and complex shapes. For components featuring

Observing and analyzing the various properties of alloy powder from the perspectives of different scanning speeds, laser power, and energy density distribution

Therefore, many studies have focused on the relationship between energy density and NiTi forming quality [25, 26].Saedi et al. [15] studied the effects of energy density on

Selective laser sintering (SLS) polymer powders involve multi-physical field transient phenomena that are critical to the optimization of SLS process parameters but

Selective laser melting (SLM) is one of the most popular L-PBF processes, where a laser source is used to fully melt and fuse the powder particles in a layer-by-layer manner in an

Laser energy density dependence of performance in additive/subtractive hybrid manufacturing of 316L stainless steel

Laser energy density dependence of performance in additive

Improving the distribution characteristics (DCH) of laser EDE will directly affect the TGR, cooling rate, and solidification rate of the molten pool, which is meaningful to enhance

Two new coefficients called “Energy Dependence Coefficient of martensitic transformation Temperature (EDCT)” and “Energy Dependence Coefficient of critical Stress

Additive manufacturing (AM) represents a significant breakthrough in the field of engineering, revolutionizing the way products and components are designed and

The laser energy density directly determines the melting state of the powder in the process of metal addictive material manufacture, and finally the microstructure and mechanical

Laser energy density dependence of performance in additive/subtractive hybrid manufacturing of 316L stainless steel. https://doi.org/10.1007/s00170-019-04372-z · Journal: The International

The present paper depicted the effect of laser energy density (ψ) on the phase change, density, microstructure, Vickers hardness, and tensile testing within the ASHM specimens.

Effects of Laser Energy Density on Microstructure and Mechanical Properties of Metal Additive Manufacturing ZHANG Zaichao, REN Guocheng, XU Shubo, WANG Hanlin, PAN Yuefei

Laser energy density dependence of performance in additive/subtractive hybrid manufacturing of 316L stainless steel The present paper depicted the effect of laser energy density ( ψ ) on

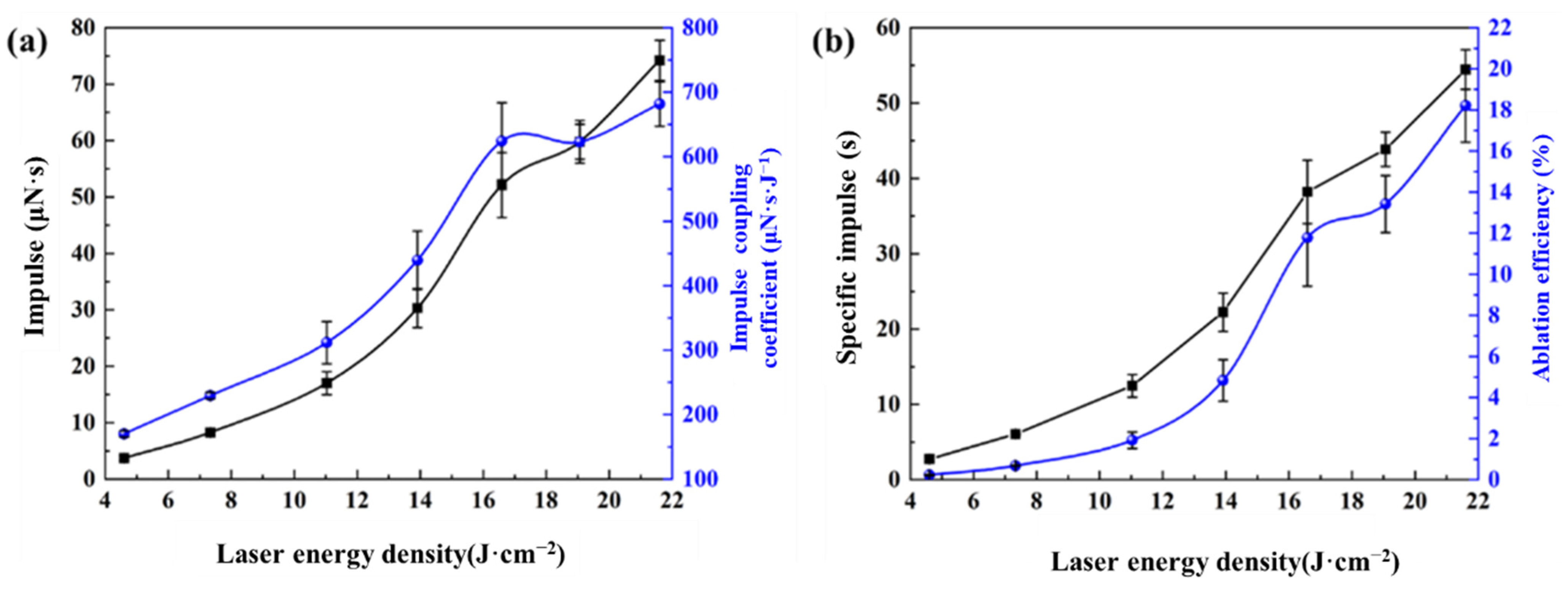

In order to investigate the influence of beam energy density distribution on the main properties of GH3625 nickel-based alloy metal parts, the beam energy density distribution was changed by

Wire-laser directed energy deposition of 316L stainless steel. We performed operando synchrotron X-ray experiments to characterize the microstructure evolution during

Porosity defects in laser powder bed fusion processes are critical, particularly when initiated in the high laser energy density regime, known as the keyhole regime. In-situ

Laser energy densiy (ED) has a determinsitic effect on the microstructure. Melt pool (MP) of different morphology and local Cr eq /Ni eq depends on ED. MP features determine the

When the laser energy density is low Microstructural evolution and mechanical performances of selective laser melting Inconel 718 from low to high laser power. J. Alloys

In laser additive manufacturing, Hofmeister et al. (2001) described the cooling rate of the molten pool in the laser processing by the following equation, which has been applied in

the laser–powder–atmosphere interaction. Powder mor-phology, laser energy density, processing strategy and atmosphere tend to play very important roles in the printing process of SLM.

The feedstock is fed through a nozzle and melted by external energy input, such as laser beam (laser directed energy deposition, L-DED) and electric arc (wire and arc additive

Dependence of microstructure, relative density and hardness of 18Ni-300 maraging steel fabricated by selective laser melting on the energy density Y. Han (Ed.) , Advances in

The effect of hatch spacing on phase transformation of SLM-NiTi is complicated. Wang [22] and Franco et al. [23] all found that the B2↔B19′ phase transformation

The main priority for additive manufacturing research must be an improvement in process repeatability and reproducibility. This paper proposes a modified energy density

- Gastrointestinal Perforation: Ultrasonographic Diagnosis

- Sardegna A Tavola Aus Berlin Speisekarte

- Umrechnen 10 Gibraltar-Pfund In Australischer Dollar

- Kindergarten Obersulm ️ Kita-Portal Kindergarten • Info

- What Do G-Keys On Keyboards Do?

- Parkhaus Karolinenstraße | Karolinenstraße Hanover Parkhaus

- The 13 Best Shoes To Have If You Have Bunions

- Der Feuerwehr-Sporttest | Feuerwehr Aufnahmetest

- Hemden Für Herren Von Homme Plissé Issey Miyake

- Text Sternenhimmel: Sternenhimmel Hubert Kah

- Ärzte Für Naturheilverfahren In Krefeld