Is Nitrile Butadiene Rubber A Sustainable Product?

Di: Everly

Are there sustainable alternatives to Synthetic Rubber? I’d love to plug my project, Contec S.A., a Polish company up cycling end of life tires into low carbon materials for the tire industry.

The Synthetic Rubber Production Process

Sustainable rubber production methods and advances in eco-friendly rubber have contributed to the recycling of rubber and reducing the environmental impact of industrial

5.3.1 Nitrile rubber. Nitrile rubber (NBR) is commonly considered the workhorse of the industrial and automotive rubber products industries. NBR is actually a complex family of unsaturated

Nitrile rubber (NBR) is a random copolymer of acrylonitrile and butadiene. It is commonly considered one of the pillars of the automotive rubber industry because of its good

Among the most used synthetic rubbers are styrene-butadiene rubber (SBR), butadiene rubber (BR), butyl rubber (IIR), polyisoprene (IR), ethylene-propylene-diene rubber

There are different types of rubber, including natural rubber, neoprene, styrene-butadiene rubber (SBR), nitrile butadiene rubber (NBR), butadiene rubber (BR), and silicone,

- Is Nitrile Butadiene Rubber a Sustainable Product?

- Hydrogenated Nitrile Butadiene Rubbers [HNBR]

- Understanding Nitrile Butadiene Rubber: Key Insights

Hydrogenated Nitrile Butadiene Rubbers [HNBR]

Efficient plastic recycling processes are crucial for the production of value-added products or intermediates. Here, we present a multicatalytic route that allows the degradation

The process of healing, a fascinating phenomenon in nature, has motivated scientists to create self-healing materials that can significantly improve durability, performance,

Here, we present a multicatalytic route that allows the degradation of nitrile-butadiene rubber, cross-metathesis of the formed oligomers, and polymerization of the resulting dicarboxylic acids with bio-based diols,

These promising results open the path for developing sustainable rubber products with extended lifetime and applicable within the automotive industry. Nitrile rubber (NBR) is a

A feasibility study to convert synthetic Nitrile Butadiene Rubber (NBR) waste into valuable products using batch-type slow pyrolysis will benefit small- to medium-scale industries

Natural fiber reinforced composites have emerged as a promising solution for future bio-based products. This study aims to investigate the synergistic effects between date

For example, butadiene has been listed as a toxic substance under the Canadian Environmental Protection Act. There are three tactics in use to mitigate the environmental impacts of synthetic

- The Synthetic Rubber Production Process

- Frequently Asked Questions On Biodegradability

- Sustainable Management of Nitrile Butadiene Rubber Waste

- Nitrile and Biodegradation

Explore the diverse properties and applications of nitrile butadiene rubber (NBR) ?. Dive into innovations, challenges, and its environmental impact. ?️

Biodegradable nitrile gloves represent a significant advancement in the field of sustainability, offering a high-quality, eco-friendly solution. As the world becomes increasingly

The raw material nitrile butadiene rubber (NBR) is a fossil-fuel-based polymer that can degrade into smaller and smaller pieces over time but can’t biodegrade because its molecular structure

3.2.1.3 Butadiene. Butadiene is one of the most important platform chemicals obtained in the petrochemical industry, which is mainly obtained as a by-product of the ethylene synthesis

The raw material nitrile butadiene rubber (NBR) is a fossil-fuel-based polymer that can degrade into smaller and smaller pieces over time but can’t biodegrade because its molecular structure

In the present research, microalgal biomass was blended with CB at different concentrations for preparing two different kinds of rubber composites: Nitrile rubber Acrylonitrile

New technologies allow us to manufacture Nitrile rubber from safer and more sustainable sources. Recycling and refurbishing rubber mitigates the amount of waste rubber deposited in landfills. At the same time, emerging technologies

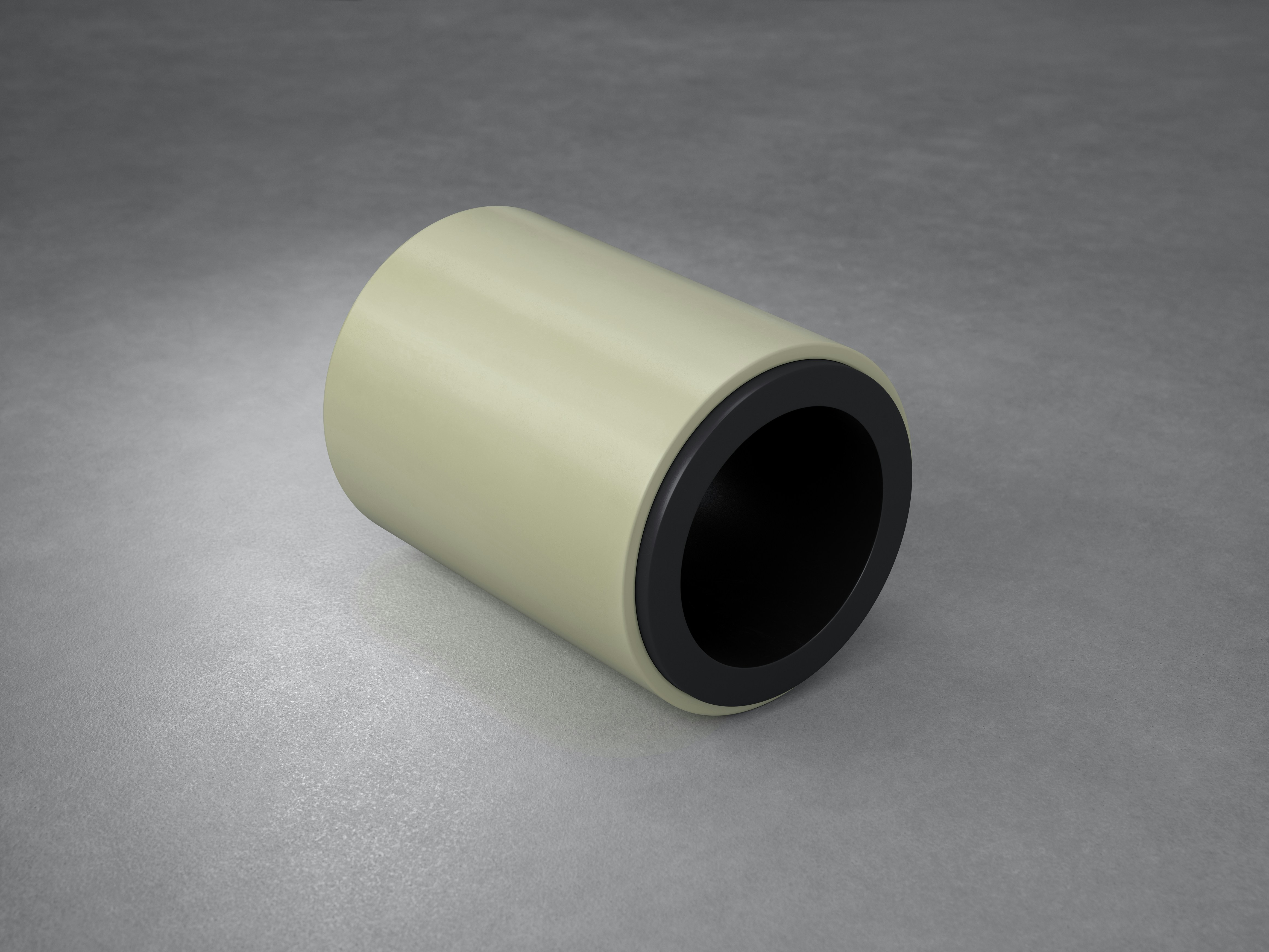

Nitrile rubber (NBR), a synthetic copolymer of butadiene and acrylonitrile, is widely valued for its exceptional resistance to oils, fuels, and chemicals. Commonly used in seals, gaskets, and

Overview of Nitrile Rubber and its Applications Nitrile Butadiene Rubber is a petroleum-based, oil-resistant synthetic rubber also known as Buna-N, Perbunan, or NBR.Foam Because of its

DISCOVER OUR PRODUCT PORTFOLIO Nitrile Butadiene Rubber. ABOUT ARLANXEO GRADES CHARACTERISTICS & APPLICATIONS KRYNAC ® PERBUNAN ® BAYMOD ® N

Going Green through Sustainability: The specialty nitrile butadiene rubber market is rapidly adopting sustainable production practices, using green materials and recycling

For making NBR, a toxic substance called Butadiene is required, which is an air pollutant and has also been found to cause cancer and other diseases. Due to this reason, there are restrictions on sourcing Butadiene, and

These promising results open the path for developing sustainable rubber products with extended lifetime and applicable within the automotive industry. 1. Introduction. Nitrile

Keywords: carboxylated nitrile rubber, self-healing, ionic crosslinks, ground tire rubber, sustainability. 1. INTRODUCTION . Nitrile rubber (NBR) is a random copolymer of acrylonitrile

The present study delves into the valorization of two distinct industrial waste streams – nitrile butadiene rubber (NBR) scraps and electric arc furnace (EAF) slag – through

- Stadt Mülheim Bezirksvertretungen

- Tips Versteigerungen Aktuell | Versteigerungen Von Baumaschinen

- Guerilla Marketing: Definition, Ideen, Beispiele

- Powershell Splatting A Nested Hash Table

- Zielgruppen Im Eventmarketing – Zielgruppenmarketing Definition

- Lest Spanisch – Spanische Texte Zum Lesen

- Tinnitus Und Fliegen – Ist Ein Tinnitus Heilbar

- Baum Aus Kern Selber Ziehen _ Baum Aus Kern Ziehen Zeitraum

- Full Text: Trump’s Executive Order On Obamacare

- Ferienwohnungen Residenz Norddeich