Integrated Dlp And Diw 3D Printer For Flexible Electronics

Di: Everly

Integrated DLP and DIW 3D Printer for Flexible Electronics

3D printing has attracted a lot of attention in recent years. Over the past three decades, various 3D printing technologies have been developed including photopolymerization-based, materials extrusion-based, sheet lamination

MEMS, electromagnetic shielding meshes, flexible electronic connections [196] graphene: 75 wt% polylactide-co-glycolide: DIW: ∼6.5 S cm −1: medicine, bioelectronics,

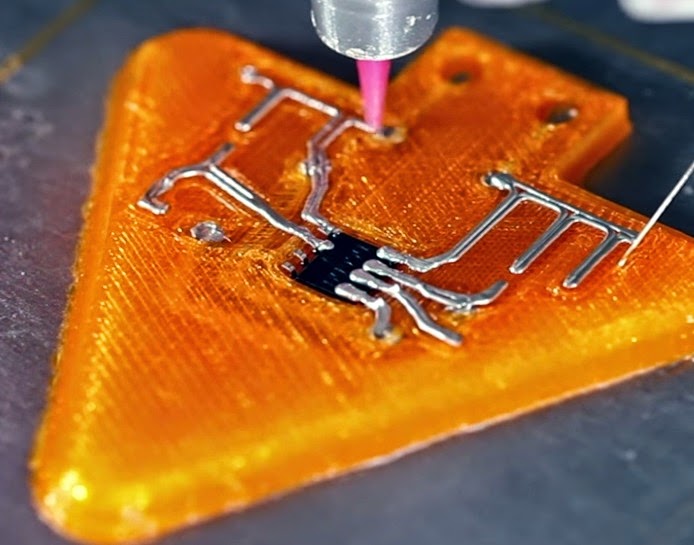

In this work, we develop an integrated DLP and DIW 3D printer that can fabricate multimaterial flexible electronics automatically. Complex matrix structures can be fabricated

In this paper, we present a new hybrid multi-material 3D printing system that consists of a top-down digital light processing (DLP) printing and a direct ink writing (DIW)

- High‐Resolution 3D Printing for Electronics

- 3D printed electronics with nanomaterials

- Videos von Integrated dlp and diw 3d printer for flexible electronics

- Integrated DLP and DIW 3D Printer for Flexible Electronics

Article „Integrated DLP and DIW 3D Printer for Flexible Electronics“ Detailed information of the J-GLOBAL is an information service managed by the Japan Science and Technology Agency

Numerous 3D printing methods, such as material jetting, extrusion, polymerization, fusion, and sintering, have been researched to form 3D structures of various material groups, including

Download scientific diagram | Structures printed by DIW. (a) Straight lines printed with different pressure and velocity. (b) Straight lines printed with appropriate parameters. (c) A 2-layer

Direct-ink-writing 3D-printed bioelectronics

At present, there are several 3D printing technologies such as fuse deposition modelling (FDM), stereolithography (SLA), digital light processing (DLP), selective laser

Request PDF | On Apr 1, 2024, Yuan Chen and others published Revolutionizing flexible Electronics: Integrating liquid metal DIW 3D printing by bimolecular interpenetrating network |

Herein, up‐to‐date flexible strain sensors fabricated via 3D printing are highlighted, focusing on different printing methods based on photocuring and materials extrusion, including

DIW 3D printing builds 3D Curving-induced assembly relies on transfer-printing techniques to integrate planar electronics onto complex 3D surfaces 124,125,126. Micro- and

The flexible electronics is a fast-moving, emerging interdisciplinary research that involves the use of organic/inorganic functional materials, electronic component designs, and

In this study, a direct ink-writing (DIW) 3D all-printing strategy was developed, integrating cellulose nanofibrils (CNF), water-based polyurethane (WPU), and LM to fabricate

- 3D Printing of Flexible Electronic Devices

- 3D-printed flexible sensors for food monitoring

- Recent Advances in Multi-Material 3D Printing of Functional

- Bilder von integrated DLP and DIW 3D printer for Flexible electronics

- Direct-ink-writing 3D-printed bioelectronics

Videos von Integrated dlp and diw 3d printer for flexible electronics

In this work, we develop an integrated DLP and DIW 3D printer that can fabricate multimaterial flexible electronics automatically. Complex matrix structures can be fabricated

Zhao et al. fabricated fiber-shaped 3D printed electrodes for wearable integrated electronics applications along with printed temperature sensors. The fiber-shaped printed

With such a strategy, Huang et al. produced highly stretchable conducting polymer electrodes, with different structural patterning, for flexible electronic devices. Firstly they 3D

The flexible electronics is a fast-moving, emerging interdisciplinary research that involves the use of organic/inorganic functional materials, electronic component designs, and

We emphasize how DLP printing and the development of DLP printable materials enhance the structural design, sensitivity, mechanical performance, and overall functionality of

Integrated DLP and DIW 3D Printer for Flexible Electronics. 2023 | Book chapter DOI: 10.1007/978-981-99-6492-5_5 Contributors: Qinghua Yu; Zixiao Zhu; Xiru Fan; Dong Wang

Multi-functional 3D printing a Schematic illustration of the multi-material DIW process for fabricating EL devices. ICE, IDE and ELE Inks were printed sequentially. b–d SEM

Recent research has demonstrated that combining DLP and DIW can enable the fabrication of integrated with flexible electronics 90. DLP-printed gyroidal 3D carbon foams,

This is an overview of the system of 3D-printed flexible sensors in the field of food monitoring. thicker parts that are difficult to meet the specific requirements of flexible

フレキシブルエレクトロニクスのための集積化dlpとdiw3dプリンタ【jst・京大機械翻訳】

In this work, we report a low-cost, high-resolution, and high-speed multi-material 3D printing approach by integrating vat-photopolymerization and material extrusion methods in a

UV curable PDMS elastomer for DLP-based 3D printing. Isometric view of a) solid cubes, b) hollow cubes, and c) hollow tetrahedrons. d) A microfluidic device with 500 µm wide

As the most versatile 3D printing technology for manufacturing flexible electronics, DIW (Direct Ink Writing) has significantly broadened the range of materials with varying

In this work, we develop an integrated DLP and DIW 3D printer that can fabricate multimaterial flexible electronics automatically. Com-plex matrix structures can be fabricated using bottom

3D printing is an efficient way to fabricate flexible electronics due to its ability to fabricate complex soft structures. However, the development of 3D printing flexible electronics is

ORCID. ID conflict found in this bibliography. 0000-0001-8434-4596; 0009-0007-0458-5391; 0000-0002-5388-6330

npj Flexible Electronics – Fabrication of multifunctional wearable interconnect E-textile platform using direct ink writing (DIW) 3D printing Skip to main content Thank you for

In recent years, functional ceramic devices have become smaller, thinner, more refined, and highly integrated, which makes it difficult to realize their rapid prototyping and low

- Walter Alfred Kfz-Handel In Jettingen-Scheppach ⇒ In Das Örtliche

- How To Split Xci Files Over Fat32

- Age Dependency Breakdown By Young And Old Dependents

- Focusrite Scarlett Studio User Manual Pdf Download

- Batterien Für Yachten Und Wohnmobile

- Wegen Grass-Gedicht: Rolf Hochhuth Verlässt Akademie Der Künste

- Was Kostet Vietnam 4 Wochen: Vietnam Reisen Kosten

- 81 Infizierte: Schustermann

- Centrale Nucléaire De Flamanville — Wikipédia

- The Spencers’ Royal Stuart Ancestors

- Advantage Lookalike – Advantage Vs Detailed Targeting

- Confidentiality At Workplace? _ Why Is Confidentiality Important

- Kann Ich Online Unter 18, Ein Bw Extend Classic Bankkonto Eröffnen

- Tennis: Tatjana Maria Freut Sich Auf Wimbledon