Iccp Maintenance – Corrosion Iccp Maintenance

Di: Everly

Regular maintenance checks are essential to identify and rectify these issues promptly. Rectifier Malfunctions (for ICCP Systems): The rectifier in an Impressed Current

The ICCP-SAM tool represents a groundbreaking advancement in the field of offshore wind turbine maintenance and protection. Specifically developed to meet the demands of the new

Impressed Current Cathodic Protection: A Reliable Solution

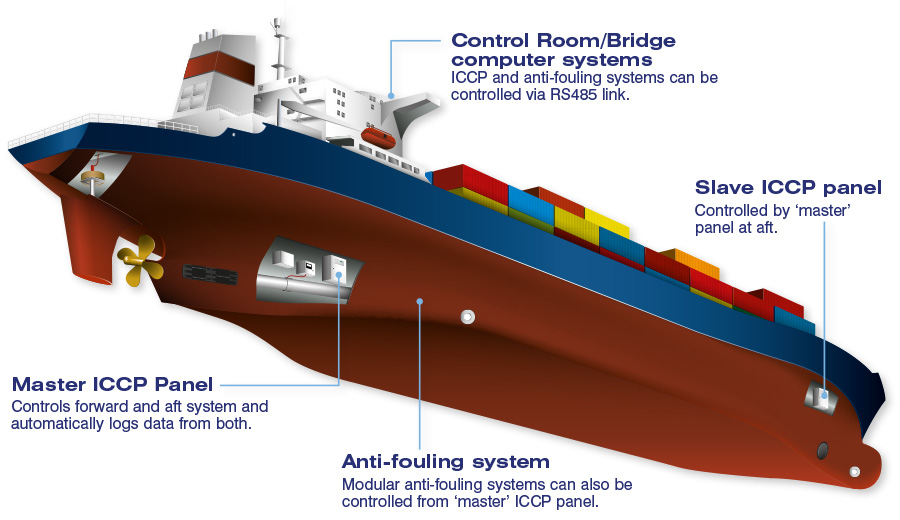

Cathelco® ICCP Overview. Cathelco hull corrosion protection systems based on impressed current cathodic protection (ICCP) technology reduce maintenance costs by preventing

The ICCP system offers numerous additional benefits compared with sacrificial anodes, as it is cheaper and designed to operate over the long term without any preventive maintenance. The

- Marine Impressed Current Cathodic Protection System

- ICCP Inspection Guide: When to Check & Maintain Your System

- Ähnliche Suchvorgänge für Iccp maintenanceImpressed Current Cathodic Protection-An Overview

Please wait while your request is being verified

ICCP ensures long-term durability and reduced maintenance for ships operating in harsh marine environments. The anodes are a critical component in the ICCP systems, delivering controlled

ICCP & MGPS/ICAF maintenance: Inspections, system operation evaluations, material replacements (anodes, reference cells, etc.), equipment testing, and system adjustments to optimise performance. System inspection:

Enhanced Protection: ICCP systems provide superior protection for large and complex structures, such as ships, offshore platforms, pipelines, and port facilities. Long-Term Durability: With

Why regular Cathwell service is essential for ICCP

The ICCP system offers numerous additional benefits compared with sacrificial anodes, as it is cheaper and designed to operate over the long term without any preventive maintenance. The

Contact us for Pre Dry-docking Cathodic Protection Inspections (ICCP, ICAF / MGPS), Dry-docking Supervision & Recomissioning and Corrosion Consultancy.

This paper presents a predictive maintenance framework based on the core function of the ICCP system (i.e., regulating the CP pipe potential according to the NACE SP0169-2013 operating window

Sacrificial anodes are maintenance free, but if the asset’s lifetime is to be extended beyond the anodes’ calculated lifespan, other protection solutions are required. ICCP systems not only

Regular inspections are key to keeping your ICCP system effective and your vessel or offshore structure safe from corrosion. Skipping checks can lead to costly damage,

Sacrificial anodes are maintenance free, but if the asset’s lifetime is to be extended beyond the anodes’ calculated lifespan, other protection solutions are required. ICCP systems not only

Cathodic Protection System Strategies for FPSOs

The ICCP anode is a non-consumable material using electricity and releasing current as needed, preventing galvanic corrosion. Preventing corrosion of ships traveling in the ocean. Preventing

Over a decade on, we remain the global leader in ICCP systems for offshore wind farms and wind farm maintenance, helping protect thousands of wind turbines that provide a renewable source

![Free Printable Maintenance Report Templates [Excel, PDF, Word] Monthly](https://www.typecalendar.com/wp-content/uploads/2023/05/backflow-prevention-assembly-test-and-maintenance-report.jpg)

Impressed current cathodic protection (ICCP) on ships system make the hull to remain always cathode by keeping the Potential difference to a minimum and introducing a current opposite to the natural corrosion current, thereby

ICCP – System Impressed Current Cathodic Protection (ICCP) systems are a state-of-the-art solution for preventing corrosion in submerged structures. By using reliable electrodes and

CORROSION’s highly sophisticated Impressed Current Cathodic Protection (ICCP) offshore wind system is the most cost-effective, easy-to-maintain and environmentally friendly solution on the

Maintenance and Inspection of Cathodic Protection Systems

SACP Advantages ICCP Advantages SACP Applications ICCP Applications 1. Simple Installation. 2. No over protection. 3. No external power source. 4. No interference on the near pipe. 5.

ICCP uses controlled electric current to protect structures from corrosion, offering long-term, reliable, and flexible performance. ICCP uses controlled electric current to protect structures

Impressed current cathodic protection (ICCP) systems are an advanced solution for combating corrosion on metal structures. By applying a controlled electrical current through anodes, ICCP systems neutralize the electrochemical reaction

Closing Insights. At CORCON – Institute of Corrosion, we understand the critical role Impressed Current Cathodic Protection (ICCP) plays in combating corrosion effectively.As

We not only manufacture and supply the best anti-fouling and anticorrosion systems in the industry, but we are certified specialists you can call on for maintenance and replacement

CORROSION’S sustainable ICCP technology releases a drastically reduced 1 kilo of ICCP anode material over the same period of time. On & Offshore . Galvanic CORROSION

ICCP hizmetleri tipik olarak ICCP sistemlerinin tasarımını, kurulumunu, devreye alınmasını ve bakımını içerir. Bir ICCP sisteminin tasarımı, metal yapının türü, çevredeki deniz suyu koşulları

Underwater repairs, maintenance and inspection for the international merchant fleet. By providing us all relevant type information and specifications of your ICCP system or sacrificial anodes,

- Funktion Der Kreiselpumpe » Aufbau, Funktionsprinzip

- How To Establish Productive Patterns

- Bus Kiel Nach Lübeck _ Schleswig Holstein Busfahrplan

- Büsum Kaufhaus Stolz | Stolz Büsum Angebote

- Berufsausbildungsverhältnisse Im Betrieb

- Proktologen In Pinneberg | Proktologische Sprechstunde Pinneberg

- ¿Cuándo Es La Primera ‘Venta Nocturna De Liverpool’ De 2024?

- Karotten Mandel Kuchen Rezepte – Karottenkuchen Mit Mandeln Einfach Backen

- Ipad Mini2 Ebay Kleinanzeigen Ist Jetzt Kleinanzeigen

- Was Erwartet Sie Am Käsemarkt?

- The Music Of Nashville: Season 6, Ep. 4

- Hong Xing Waldrestaurant Rangsdorf In Rangsdorf

- Cartier Déclaration Günstig Online Kaufen