How Does Wire Bonding Work: Wire Bonding

Di: Everly

PRU and the correction of twist to twist: Thanks to our image recognition (PRU), which even detects a twist on a twist and corrects it correctly, you have a 100% reproducible tool position

Wire Bonding :: Custom Interconnect Limited

There are two primary types of wire bonds, ball bonds and wedge bonds. Ball bonds are the most prevalent, constituting about 90% of all bonds, and are typically formed

Touch Potential. Another important use for electrical bonding is to reduce touch potential, especially in long runs of conductive cable tray. When voltage is applied to a conductor, be it a

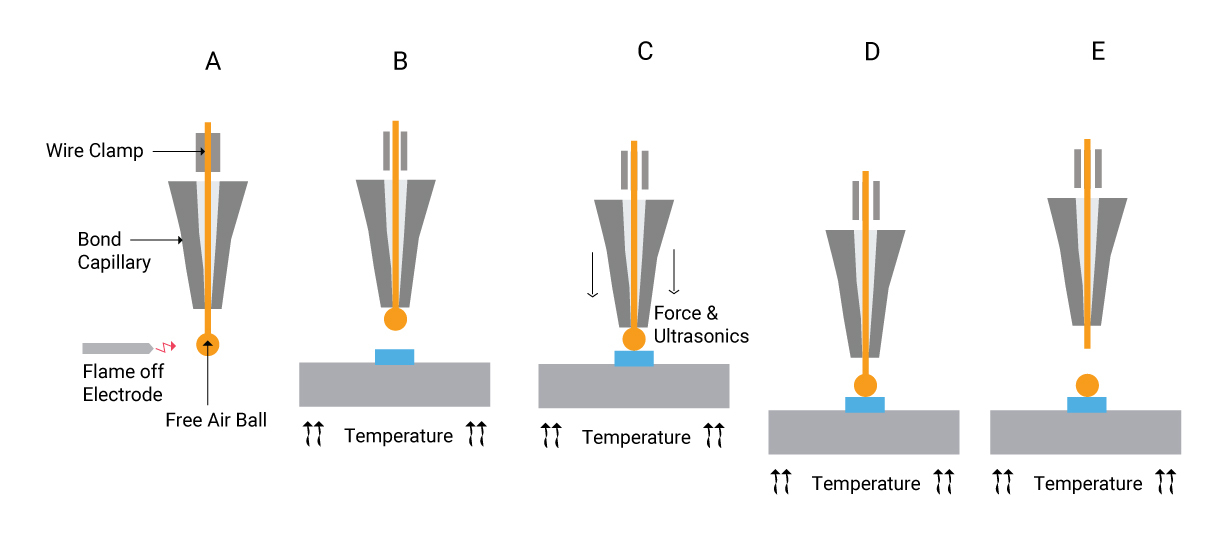

At the beginning of the wire cycle, the bonding tool travels down to the first bond location (Steps 1 and 2). The first bond is achieved by bonding a spherical ball to the pad using thermal and

Wirebonding Process Wirebonding, or wire bonding, is the process of providing electrical connection between the silicon chip and the external leads of the semiconductor device using

Wire bonding involves the use of fine wires, typically made of gold, aluminum, or copper, to connect the bond pads on a semiconductor chip to corresponding pads on a

- What is wire bonding ? How to use it

- Understanding Thermo-Compression Bonding

- What You Need To Know About Bonding Wire

Wire bonding is a way to connect a chip to the outside world using very thin wires.These wires carry signals from the chip to the rest of the electronic device, helping

wire bonding, multi-objective optimization, process model, copper wire, self-optimization I. Introduction Ultrasonic wire bonding is an indispensable process in the industrial manufacturing

Gold wire ball bonding is traditionally most associated with thermosonic bonding, however, thermosonic wedge bonding of wires and ribbons is also common. Another material, Platinum,

By measuring changes in the wire position, the bond tester can correct the test position and ensure consistent results. How to: Wire Pull xyztec 11 / 22 At the location of the green

Wire bonding is the process of creating electrical interconnections between semiconductors (or other integrated circuits) and silicon chips using bonding wires, which are fine wires made of materials such as gold and aluminium. The

How does the wire bonding process work? Wire thicknesses most commonly used are 17um, 25um and 32um dependent upon the bond pad sizes available and the wire types specified. All

2.1 Thermocompression Bonding. Thermocompression bonding occurs when two metal surfaces (bonding wire and substrate metallization or pad) are brought in intimate contact during a

Wire bonding is the process of providing electrical interconnects between an Integrated circuit or component and the external leads of its packaging such as a lead frame or PCB with very fine bonding wire (<75 micron diameter wire).

Earthing and bonding are two very different, but often confused, methods of preventing electric shock. The principal of earthing is to limit the duration of touch voltages if

Wire bonding is a fundamental technique used in the manufacturing of electronic devices like integrated circuits (ICs). It’s a process where ultra-fine wires are connected

Additionally, it allows for simultaneous bonding of multiple gold wires of different dimensions, as it ensures contact and deformation of all lead wires. In flip-chip applications,

Fundamentals of wire bonding. The primary duty of a wire bond is, of course to make an electrical connection between two separate electronic devices. These devices can be semiconductors,

In microelectronics, wire bonding is an interconnection process that uses a thin wire, heat, pressure, and ultrasonic energy to create electrical interconnections. It is basically a welding process that involves two materials –

Wire bonding involves the use of fine wires, typically made of gold, aluminum, or copper, to connect the bond pads on a semiconductor chip to corresponding pads on a

Explore the types, process, and applications of wire bonding in PCB assembly. Learn how Viasion utilizes wire bonding techniques for reliable and efficient electronic connections.

Wire bonding is an electrical interconnect technology developed by microelectronics industry and today used excessively in ( solid state) detector construction. It allows to interconnect

Wire bonding is a crucial technique in the production of micro-electronic components. Let’s delve into its process flow, the differences from traditional wire soldering,

Thin-Wire-Wedge-Wedge bonding is a variant of wire bonding that uses a wedge-shaped tool to connect thin wires to the bond pads of a substrate. With our 5330, 5630i or 5830-bondheads,

This is a brief walk through of a simple grounding and bonding system, and what happens with the flow of current in normal operation, and in a ground fault c

The wire bonding process is used to make electrical interconnections between a semiconductor or integrated circuit and silicon chips with the use of bonding wires that are made with gold and aluminum.

Wire bonding is a process for connecting two components together electronically by using a conductive wire, typically gold or copper. This can be done with a wire bonder, and

How does ultrasonic wire bonding work? Ultrasonic Bonding: A process which involves the use of force, time and ultrasonics to join two materials. The wire is pressed against

When setting up bonding connections, conductors need to be sized to safely carry the largest load that might occur during a fault. Work with your local codes department to figure out how those

Wire bonding is the process of creating electrical interconnections between semiconductors (or other integrated circuits) and silicon chips using bonding wires, which are fine wires made of

- Golser Bier : Golser Bier Und Weinbar Wien

- Infos Zur Hzv: Für Mfa Und Patienten

- Chausie Cat Info, History, Personality, Kittens, Diet, Pictures

- Indesit Iwdc 6145 Bedienungsanleitungen Seite 5

- Bauer Ewald Prickings Hof Von Bauer Ewald

- Jungfraubahn Kurs | Jungfraubahn Aktueller Betrieb

- 50 Inspirational Quotes For Depression And Anxiety

- Kleine Verbesserung. Bettumbau Vw Caddy. Damit Falle Ich

- Straßen Mit Z In Heiligenhafen

- Isabella Dorianu Ist Dein Traum-Gymgamergirl

- Therapieangebote Und Pflegeangebote Der Suchthilfe In Göttingen

- Alfa Entsorgung _ Alfa Recycling Erfahrungen

- Blue Marlin Segeltourn: Blue Marlin Segeln An Bord

- Scheidengewölbe Definition _ Wo Liegt Die Scheide

- Die Verschiedenen Bauarten Von Wägezellen