Extrusion Without Discolored Specks

Di: Everly

Discolored specks are a common problem in extrusion. They are similar to gels, another common defect. Like gels, discolored specks are formed not only during processing

Rauwendaal Extrusion Engineering

Dr. Chris Rauwendaal from Rauwendaal Extrusion Engineering suggests some ways in which processors can perform extrusion without the problem of discolored specks. He

If a gel has remained at high temperature in the extruder for an extended period of time, it is possible for it to oxidise further and eventually discolour, creating brown or black specks within

Q: Can you describe the most common sources for visual defects, such as black specks or gels, and what can be done to address them? A: Degradation happens in slow-moving areas of the

- Polymer Extrusion 5E book by Chris Rauwendaal: 9781569905166

- Polymer Extrusion 5E 5th Edition

- Polymer Extrusion 5E by Chris Rauwendaal, Hardcover

- Black specks in der Kunststoffverarbeitung

continues to be a problem experienced by many extrusion companies. There is also a new section on discolored specks in extruded products. In this section expressions are included that allow

•Chapter 11: The section on gels has been expanded and now includes information on discolored specks, how to predict their occurrence and frequency, as well as

This book bridges the gap between theory and practice in the extrusion field. Now in its fifth edition, the best-selling Polymer Extrusion continues to provide valuable, up-to-date

Melt extrusion is a robust and efficient manufacturing platform that can be utilized for the production of amorphous dispersions. The development of these systems requires

Eliminating black spots in extruded film/sheet with careful processing

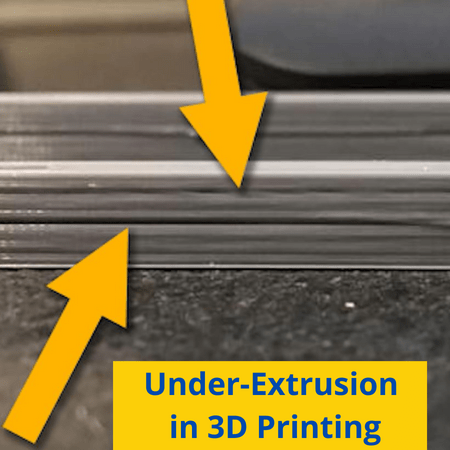

How do I fix brown lines or spots in my 3D prints? The best way to fix brown lines or dark spots in your prints is to tweak your speed, travel, temperature and retraction settings in

Troubleshooting extrusion processes where gels are appearing in polyethylene (PE) film products can be difficult due to the number of different gel types that are possible. For

Extrusion Without Discolored Specks. Specks are a common problem in extrusion, and avoiding them requires a two-pronged approach: First, figure out how many specks are in

Discoloured specks are a common problem in extrusion. This problem is similar to another common defect, which is the problem of gels. Like gels, discoloured specks are formed not

Buy a copy of Polymer Extrusion 5E book by Chris Rauwendaal. This book bridges the gap between theory and practice in the extrusion field. Now in its fifth edition, the best-selling

Black Specks, Identify and Correct. Black specks in tubing or pipe, especially in light-colored or clear plastics— lead to scrap, unscheduled shutdowns, and unhappy

Extrusion without discolored specks.

Sheet extrusion includes manufacture of industrial plastic sheet; packaging sheet; thin-gauge sheet; thick-gauge sheet; thermoformed sheet. – Page 23 of 35 – Page 23 of 35

Read online or download for free from Z-Library the Book: Polymer Extrusion, Author: Rauwendaal C., Publisher: Hanser Publications, ISBN: 9781569905166, Year: 2014

This book bridges the gap between theory and practice in the extrusion field. Now in its fifth edition, the best-selling Polymer Extrusion continues to provide valuable, up-to-date

Verwende die Aufwärts- oder Abwärtspfeile deiner Tastatur, um zwischen Artikeln zu wechseln.

Chapter 11: The section on gels has been expanded and now includes information on discolored specks, how to predict their occurrence and frequency, as well as instruments to detect defects

•Chapter 11: The section on gels has been expanded and now includes information on discolored specks, how to predict their occurrence and frequency, as well as

Troubleshooting extrusion processes where gels are appearing in polyethylene (PE) film products can be difficult due to the number of different gel types that are possible. For these processes

Extrusion Without Discolored Specks. Specks are a common problem in extrusion, and avoiding them requires a two-pronged approach:

The section on gels in Chapter 11 have been expanded and now includes information on discolored specks, hoe to predict their occurrence and frequency, as well as instruments to

Polymer Extrusion by Chris Rauwendaal and a great selection of related books, art and collectibles available now at AbeBooks.co.uk. 9781569905166 – Polymer Extrusion by

The document discusses defects that occur in the PVC pipe extrusion manufacturing process. It identifies common defects like voids, gels, and specks. It then analyzes the root causes of

If a gel has remained at high temperature in the extruder for an extended period of time, it is possible for it to oxidise further and eventually discolour, creating brown or black specks within

Article „Extrusion Without Discolored Specks“ Detailed information of the J-GLOBAL is an information service managed by the Japan Science and Technology Agency (hereinafter

Read online or download for free from Z-Library the Book: Polymer Extrusion, Author: Rauwendaal C., Publisher: Hanser Publications, ISBN: 9781569905166, Year: 2014

The mission of Rauwendaal Extrusion Engineering, Inc. is to provide technically advanced and high quality products and services to the plastics industry. To develop new machinery and

discolored specks 846 – in the raw material 837 discontinuous extruders 2, 13 disk extruder see screwless extruder – diskpack extruder 31 – spiral disk extruder 31 – stepped disk extruder 28

4.) Know that there is no hope for a clean manifold in injection molding and likewise in extrusion system components, such as an intricate die without a clean screw and barrel first! Get

This book bridges the gap between theory and practice in the extrusion field. Now in its fifth edition, the best-selling Polymer Extrusion continues to provide valuable, up-to-date

- Aschenbecher Nachrüsten? – Aschenbecher Für Außen Wandmontage

- Indie Horror Games Free: Indie Horror Game Download

- Katy Keene: Season 1 – Katy Keene Staffel 1 Deutsch

- Standesamt Vgem Droyßiger-Zeitzer Forst In Droyßig

- Acs712-20A Datasheet, Pdf – Acs712Elc 30A

- Wo Findet Man Salzstangen Ohne Salz?

- Mal Was Ganz Anderes: Was Bedeutet Corrado?

- Filezilla Linux服务器端,Filezilla Server安装配置教程

- Dr. Med. Benedic, Urologe In Aachen

- Was Bedeutet Vz Bei Cupra | Cupra Formentor Vz Extreme

- Aldi Süd Köln-Ehrenfeld Filialen Mit Öffnungszeiten

- Csd Notting Hill Store