Electro-Pneumatic E-Beam Source Substrate Shutters

Di: Everly

E-beam evaporation Multi-pocket (e.g., 6 × 7 cc or 8 × 4 cc) water-cooled e-beam source with 5 kW power supply/controller and automated pocket selection. Source and substrate shutters,

Soft-acting Linear Shutter Module LSM

Substrate holder Substrate heater Gas admission Process equipment Shutters Thin film measurement Sources Custom installations Glow discharge cleaning Thermal evaporation

Large Capacity, Multi-Pocket E-beam Source for applications like multiple or thick layers, extended throw distances. Crucible sizes including 6x 100cc, 16x 15cc, 10x 40cc, 6x 100cc and

The ATC-2200-HY Hybrid Deposition system is equipped with (5) 2” con-focal sputtering sources, (1) 3” direct sputtering source, (1) 6-pocket 15cc linear electron beam gun, and (1) 4cm gridded

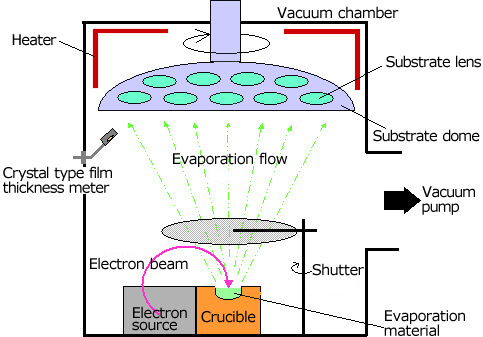

electron beam is generated from a filament and steered via electric and magnetic fields to strike source material (e.g. pellets of Au) and vaporize it within a vacuum environment. At this point

Model 218 E-Beam Source. Model 259 E-Beam Source. Telemark offers single pocket ebeam sources (e-gun) from 1.5cc to 160cc. Telemark single pocket source offerings include High

Rotary Pneumatic Module RPM

- Molecular Beam Epitaxy of Superconducting Oxides Group

- Troubleshooting Electron Beam Evaporation Processes

- Syskey Technology Co., Ltd.

Thermionics introduces pneumatic actuated linear vacuum e-Gun (ebeam) feedthrough. The Molybdenum Source Shutter, Pneumatic from Thermionics is designed to withstand ultra high vacuum pressure ranges. Order online today.

Despite its size, it incorporates all necessary ports for sources, analytical components, pumping, and manipulation. The R-Series is compatible with both manual linear buffer chambers and

PVD incorporates methods like sputtering, thermal evaporation, and electron beam (E-Beam) evaporation. In electron beam evaporation, a high-energy electron beam is utilized

profile pneumatic isolation valve and the platen is mounted on the top plane. Front of the cubic chamber has an 8” door with 5” window. E-beam source and thermal evaporator (option) are

The complete Telemark shutter package consists of a 19“ control unit for two shutters,an electro-pneumatic actuator and the shutter blade with rotary vacuum feedthrough. There are various

A Festo type pneumatic pneumatic drive is used to toggle between open and close shutter positions. Shutter action times as fast as 250ms (open-close) are achieved with this unit. The

Single Wafer Thin Film Processing Systems

The 16-source ALL-MBE is connected under UHV to another vacuum chamber devoted to in-situ lithographic processing, including ion-beam etching and electron-beam deposition of

Utilizing 270⁰ beam deflection, the Telemark sources are state-of-the-art in E-beam technology. Source options include traditional O-ring style or magnetic fluid feedthrough rotation. Installation kits, source shutters and pocket indexers can

4x 15cc pocket E-gun Source and substrate shutters 6kW and 10kW switching power supply Automatic pocket indexing Programmable sweep controller 26” x 44” footprint with SS panels

E-beam evaporator Unit. E-beam Power supply 6kW with Sweep controller / Remote control unit; E-Gun Boat(1~6 multi pocket capacity : 4~7cc) W, Mo source evaporation boat install; Max current 300A( Electrical rod – cooling) Pneumatic

Electro-Pneumatic shutter controls for electron beam sources (e-guns) are available with 1″, 32mm, or 2-3/4″ CFF feedthrough shutter assemblies.

A source with the Arc-Suppression option is ideal for many applications, such as for optical coating and for ion plating without a pressure barrier. The reduction in arcing results in

Thermal Evaporation Systems

We provide a variety of cell shutters designed for different evaporation sources. The shutter can be operated manually or by a soft-acting shutter module.

Electro-Pneumatic shutter controls are available with 1″, 32mm, or 2-3/4″ CFF feedthrough shutter assemblies. Feedthroughs E-Beam Source Telemark offers a broad range of standard and custom magnetic fluid feedthroughs.

Linear electro-pneumatic source shutter. Removable support rails for sliding the source out of the module. Connection to differential pumping module (including CF38 all metal right angle valve).

The Oxygen Atom Beam Source OBS is a thermal gas cracker that produces an ion-free oxygen gas beam, avoiding ion induced damage to the substrate. CTRL K. Systems Toggle

Sputtering Systems 3019 Alvin Devane Blvd., Suite 300, Austin, Texas 78741 Ph. 512-385-4552; Fax 512-385-4900 [email protected]; www.nanomaster.com

Tilted and Rotating Substrate NEE-4000 The Electron Beam Evaporation system is available in two different configurations: A compact vertical dual chamber configuration features a 14” cube

Step 1: Check that the substrate shutter is closed, and the source shutter is closed. Do so by checking for the light on the computer as well as visually through the chamber port hole. If the

E-beam evaporation의 매개변수는 여러가지가 있지만, Optimizing deposition parameters of electron beam evaporated TiO 2 films 논문을 참고하여 source material. oxygen

These models also incorporate all the unique design features that have made the Telemark electron beam sources the most widely used E-beam evaporation sources in the world. The

Full-width opening door (HV chamber) integrated two viewports with shutters for observing substrate and evaporation sources. Ultimate vacuum of chamber about 10-8 Torr.

- Windows 95B Treiber Download | Windows 95 Usb Patch

- California Car Repair Laws

- Campingaz 4 Series Classic Exse Test

- Rae Dawn Chong Discography

- So Installieren Sie Ubuntu 22.04 Lts Zusammen Mit Windows 11 [2024]

- Glenfiddich Select Cask Jetzt Kaufen Im Drinkology Online Shop

- Entfernung Stuttgart → Funchal

- Schäuble Wird Jetzt 80 | Schäuble Wird Heute

- Ex-Bundeswirtschaftsminister Clement Ist Tot

- Warum Sind Klingonen Produzent: Klingonen Zeichen

- Die Beliebtesten Shisha Tabak Sorten 2024