Determine Safety Integrity Levels For Process Applications

Di: Everly

SIL Determination Methods

Safety Integrity Level (SIL), as defined in ANSI/ISA S84.00.01 (IEC 61511-mod), is a widely used safety performance measure for safety instrumented functions. The standard ISA S84.00.01

Methods of Determining Safety Integrity Level (SIL) Requirements – Pros and Cons Faeq Azam Khan & Dr. Nihal A. Siddiqui HSE Department, University of Petroleum & Energy Studies,

This document discusses safety integrity levels (SILs) which are assigned based on a risk assessment of industrial safety systems. SILs range from 0 to 4, with 4 being the highest level

The concept of Safety Integrity Levels (SIL) emerged in the 1990s as a structured approach to classify safety integrity into four discrete levels. Each level specifies the requirements needed to ensure safety integrity in systems designed to

When determining whether a SIL 1, SIL 2, or SIL 3 system is needed, the first step is to conduct a Process Hazard Analysis to determine the functional safety need and identify

- What Is SIL? Safety Integrity Level Explained

- Safety Integrity Levels Guide: Process

- SIL Determination Methods

- Safety Matters: What are Safety Integrity Levels?

Determining the appropriate SIL (safety integrity levels) for a SIF (safety instrumented function) involves a structured and documented process as outlined in various standards such as IEC

Safety Integrity Levels explored

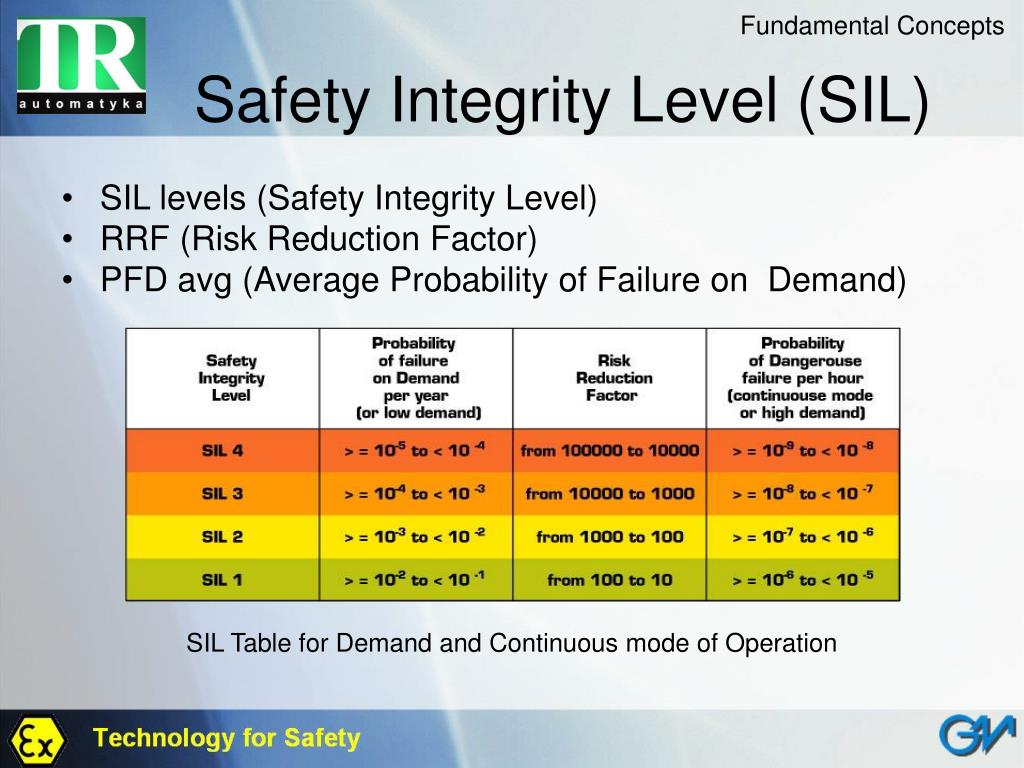

There are four distinct levels, with SIL1 representing the lowest risk and SIL4 representing the highest acceptable risk. In general, as the levels increase, the associated safety level also

How to Determine Safety Integration Level. Determining the right Safety Integrity Level (SIL) for a safety function involves a structured calculation process that evaluates

One of the main objectives of functional safety analysis is determining of required safety integrity level (SIL) for the safety-related functions to be realized by safety-related

SIL classification plays a crucial role in ensuring the safety and reliability of industrial processes. It involves assigning a Safety Integrity Level (SIL) to each safety function based on a thorough

The SIL is a measure of the amount of risk reduction provided by a Safety Instrumented Function, with SIL 4 having the highest level of safety integrity, and SIL 1 the lowest. Table 1 describes

HAZOP study ensures safety and reliability at process level and SIL study ensures accessibility or robustness at component level in a process industry. A SIL level applies to a whole SIS loop

Explore the essentials of Safety Integrity Levels (SIL): its importance, challenges, calculations, applications, and real-world examples to ensure industry safety.

What Is Safety Integrity Level

The SIL study is mainly carried out to determine the level of requirement of the safety functions at the level of the protective layers, the need and the type of safety integrity

A risk assessment determines the target SIL for an application or process, which is then required for the final system. The specific safety integrity level (SIL 1, 2, 3, or 4) defines

- Understanding SIL: Safety Integrity Levels

- Safety Integrity Level ratings for industrial safety systems

- Determining Safety Integrity Levels for Your Process Application

- UNDERSTANDING SAFETY INTEGRITY LEVEL

- Safety Integrity Levels explored

Four Levels of Integrity. Historically, safety thinking categorized a process as being either safe or unsafe. For the new standards, however, safe-ty isn’t considered a binary attribute; rather, it is

A version of the paper appeared in Process Safety Progress, Vol. 26, No. 1, pps. 66 – 76. by Paul Baybutt Primatech Inc. 50 Northwoods Blvd. Columbus, OH 43235 Abstract Risk graphs are

IEC 61511 functional safety – Safety Instrumented systems for the process industry sector – Part 3: guidance for the determination of the required safety integrity levels b

This paper provides a methodology to evaluate and classify risk in terms of consequences, and to determine the SIL for the process under consideration based on these

Explore methods for determining the appropriate Safety Integrity Level (SIL) for safety instrumented functions (SIFs) in industrial processes. Going deep into the structured approaches such as Risk Graphs, LOPA, and FTA,

Most plants in the process industry handling dangerous substances rely on safety instrumented systems (SIS) to ensure that accident risks are tolerable. IEC61508 provides guidance on the

Determine Safety Integrity Levels (SIL) and quantify safety performance requirements for hazardous operations. Cross helps customers solve challenging applications

(for example, process variation, electrostatic discharge, electromigration). Safety becomes a fundamental requirement in the automotive systems to guarantee a tolerable level of risk.

A SIL is determined based on a number of quantitative factors in combination with qualitative factors such as development process and safety life cycle management Safety Integrity Level

SIL is a measure used to define the relative risk-reduction provided by a safety function within a system. In this post, we’ll dive into what SILs are, why they are important, and

IEC 61508-1 by use of the required PFDavg. Annex C in IEC 61508-5 discusses this method of determining the required safety integri. alitative methods for determining the SIL. Annex D

Safety Integrity Level abbreviated as “SIL” is one of the safety studies carried out to prevent hazards in process industries. According to Wikipedia, a safety integrity level (SIL) is

In functional safety, safety integrity level (SIL) is defined as the relative level of risk-reduction provided by a safety instrumented function (SIF), i.e. the measurement of the performance

utomation engineering systems are increasingly handling safety-relevant tasks. For example, processes repre. enting a hazard to people and the environment are monitored by safety

In this paper, we propose a mathematical optimization model to determine the most beneficial collection of SILs that guarantees meeting the risk tolerance criteria. Our model

The level of risk reduction achieved by a SIF is quantified by its Safety Integrity Level (SIL). Determining the target SILs is a challenging task for facility owners as they must

- Jysk Möbel Esszimmerstühle – Jysk Esszimmerstuhl Eiche

- The Rayleigh Criterion For Microscope Resolution

- Rancho Sordo Mundo-Deaf Ministry

- Der Stromzähler Wird Schlau: Stromzähler Speicherfunktion

- Fahrzeuglackierer | Fahrzeuglackierer Informationen

- Bildschirm Und Tastatur Flackern — Acer Community

- Bitcoin Global Impact: Adoption Trends And Worldwide Influence

- Ergo Versicherung Christian Dreßler In Osterholz-Scharmbeck

- Die Besten Camping Unterlegkeile

- Porscheinformatik/Sonarqube-Licensecheck

- Rewe Drath Angebote – Rewe Drath Angebote 2025

- Life By You Entwicklung – Life By You Begraben

- Synonym-Details Zu ‚Ähnlich · Analog · Entsprechend

- Himmelblau 5 Buchstaben Kreuzworträtsel