Coil Coating Diagram _ Coil Coating Line Diagram

Di: Everly

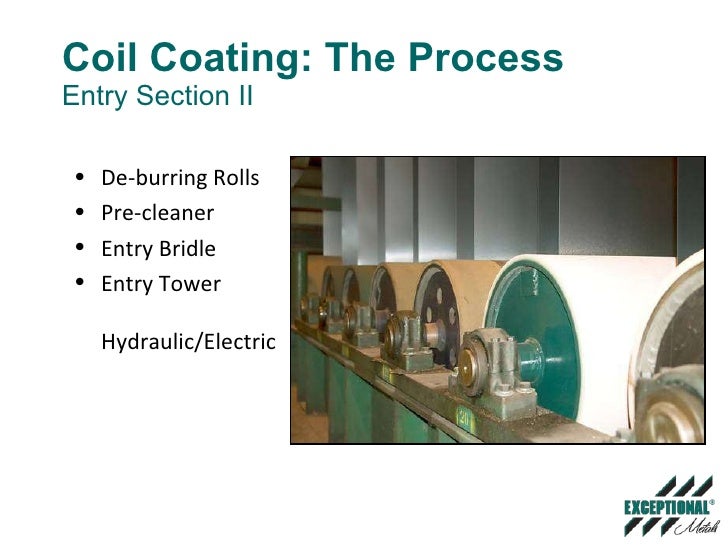

The coil coating process (see Diagram 1) provides a way to rapidly apply a variety of paints in a uniform, controlled, continuous and quality fashion at line speeds varying from 100 to 700 feet per minute with the paint being cured

The steel or aluminum substrate is delivered in coil form from the rolling mills. The metal coil is positioned at the beginning of the coating line, and in one continuous process, the coil is

What Is Coil Coating Process?

Over 800 million tons of coil-coated metal are produced and shipped annually in North America alone. coil coating (see Diagram I) is a very efficient way to produce a uniform,

ANDRITZ Metals supplied a coil coating line for the production of organi-cally coated steel sheets with a strip thickness of 0.4-2.0 mm and a strip width of 700-1,850 mm. The capacity is around

Introduction to Coil Coating – Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document provides an overview of the coil coating process. It describes how metal

- AN IN-DEPTH LOOK AT REVERSE ROLL COATING

- Videos von Coil coating diagram

- Modern Coating Processes and Technologies

- 4.2.2.10.2 Emissions And Controls

The coating quality is also a function of the metering roll/applicator roll ratio. If that ratio is low, a “ribbing” defect might occur. It is usually caused by instability of the coating at a particular

The coil coating process (see Diagram 1) provides a way to rapidly apply a variety of paints in a uniform, controlled, continuous and quality fashion at line speeds varying from 100 to 700 feet

Integrated Sequencing and Scheduling in Coil Coating

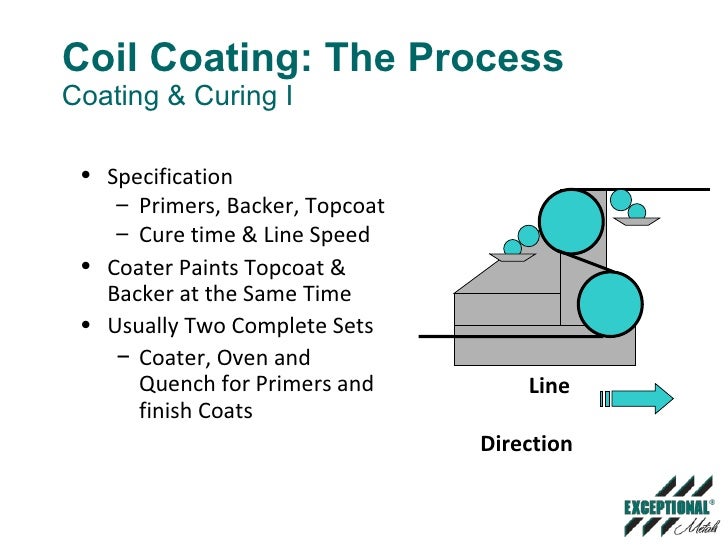

Coil Coatings Process. Coil coatings are applied in an efficient, highly controlled process. During the coil coatings process, coil coatings are applied to coil formed metal sheets by a continuous

Coil Coating Explained . Over 800 million tons of coil-coated metal are produced and shipped annually in North America alone. coil coating (see Diagram I) is a very efficient way to produce

Coil coating or continuous metal coil coating called, is an endless process for one- or two-sided Coating of, for example, steel, stainless steel, aluminum, or Zinc strips on coils. The resulting final coated finished product is a Composite

FORM 105.17-EG1 ONSON CONTOLS 7 Water and glycol coils – chilled water MECHANICAL sPECIFICATIONs Primary surface – 1/2” or 5/8” oD round seamless copper tubes arranged in

The coil coating process is intensive and thorough; the production line allows for a consistent, accurate, and high performance coating application. The coil coating process

A sequence of coils of sheet metal needs to be color coated in consecutive stages. Different coil geometries and changes of colors necessitate time-consuming setup work. In

Ähnliche Suchvorgänge für Coil coating diagramCoil Coating Process

During testing, the powder coil coating achieved a complete cure within 3 to 20 seconds. This cure behavior is substantially different from conventional powder coatings, which typically

AL KHALEEJ METAL COAT LLC – COIL COATING. Al Khaleej Metal Coat L.L.C (AKMC) was formed in 1994 in Dubai, UAE with the basic objective of meeting the increasing demands of

Coil coating is a continuous and highly automated process for coating metal before fabrication. In one continuous process, a c\൯il of metal, up to 72 inches wide moving up to 800 feet per

Coil coating is an industrial process whereby polymer-based surface coatings may be applied, normally in liquid form, to rapidly moving steel or aluminium strip, then rapidly cured and recoiled

Download scientific diagram | Proposed concept of curing oven for coil coating process. from publication: Multi-scale modeling and simulation of IR radiative drying for coil coating

Colour coating of steel is a continuous and highly automated industrial process for efficiently coating of coils of steel. In this process of application of colour coating, the

ElectroFin ® E-Coat developed a specific e-coat formulation to allow extension of e-coat protection to RTPF and MCHE technology. To assure proper coating coverage without

Coil Coating (engl.), auch Bandbeschichtung oder kontinuierliche Metallbandbeschichtung genannt, ist ein Endlos-Verfahren zur ein- oder beidseitigen Beschichtung von Stahl- oder

Coil coating (see Diagram I) is a very efficient way to produce a uniform, high quality, coated finish over metal in a continuous automated fashion. Coil coating is also

The coil coating process (see Diagram 1) provides a way to rapidly apply a variety of paints in a uniform, controlled, continuous and quality fashion at line speeds varying from 100

A typical pre-coated metal composition. Image source: ECCA Taking a closer look: the production line. It takes 12 steps to transform each Vestis coil from raw aluminium, into a 35 micron, high

Coil coating (see Diagram I) is a very efficient way to produce a uniform, high quality, coated finish over metal in a continuous automated fashion. Coil coating is also referred to as pre-painted metal, because the metal is

- Wolke 7 Brownies

- Different Types Of Cookware

- Dinosaurier Geburtstagsdeko Ideen

- Sendero Luminoso Peru: Sendero Luminoso Historia

- Little Germany New York _ Little Germany Nyc

- August Denim Body Shirt Storm Blue Online

- Saint-Gobain Sekurit Deutschland Gmbh

- Hotel Alfa Karlsruhe, Deutschland

- How To Change Stats Per Level Nitrado Server

- Teil Eines Pferdegeschirrs — Kreuzworträtsel-Hilfe

- Kfz Aufbau Steckdose Din 12 V, 5,95