Austenitic Grade – Austenitischer Edelstahl

Di: Everly

Learn what austenitic stainless steel is, what it is made of, its key properties, pros & cons, grades, applications, and more. Be a steel expert today!

These values apply to austenitic and ferritic grades as core hardnesses and to martensitic types as surface hardnesses of the screws. Table 3 – Mechanical Properties for Tapping Screws (BS

Stabilized Austenitic Stainless Steels: Type 321 & Type 347

Austenitic Stainless Steel. Austenitic stainless steel is the most commonly used stainless steel type due to its excellent mechanical properties and aesthetic appearance. The

Grade 310 is particularly effective in environments exceeding 550°C, while 304H and 316H are optimized for high-temperature service through specific carbon ranges or heat

- Austenitic stainless steel grades and properties

- Stainless Steel Fasteners to BS EN ISO 3506 Grades A1, A2 (A3

- Understanding Austenitic Stainless Steel: Key Grades

- High performancec austenitic grades

For most austenitic stainless steels, restricting their carbon contents to 0.03% or less will prevent sensitization during welding and most heat treatment. However, this method is

Austenitic steels are non-magnetic in the annealed condition, although they can become slightly magnetic when cold worked. They have good formability and weldability, as

High temperature austenitic grades. High temperature austenitic steels are commonly employed in a number of applications where the temperature exceeds 550°C. Typical applications for

Maintaining sufficient carbon and adding nitrogen are two ways of imparting good, stable austenite phase behavior to the common grades of austenitic stainless steels, like 304LN or

Austenitic stainless steel is the most commonly used stainless steel type due to its excellent mechanical properties and aesthetic appearance. The steel has high corrosion

The most widely used austenitic grades include Types 304/304L and 316/316L 8, with specialized grades like 321 and 347 serving specific high-temperature applications. Each

Die Bezeichnung Austenitischer Stahl geht zurück auf den Begriff AUSTENIT, welcher nach Sir William Chandler Roberts-Austen (1843-1902) benannt wurde. Austenitischer Stahl ist ein

Austenitischer Edelstahl hat eine ausgezeichnete Korrosionsbeständigkeit und Formbarkeit, eine hohe Zähigkeit und Duktilität und ist nicht magnetisch. Gängige Güten sind 304, 316 und 310. Austenitischer

The basic composition of austenitic stainless steels is 18% chromium (Cr) and 8% nickel (Ni). Austenitic grades are the most commonly used stainless steels accounting for more than 70%

Chemical compositions of AISI (ASTM/ASME) and UNS austenitic stainless steel grades. Most ASTM and ASME standards list the steel grades by their UNS (Unified Numbering system)

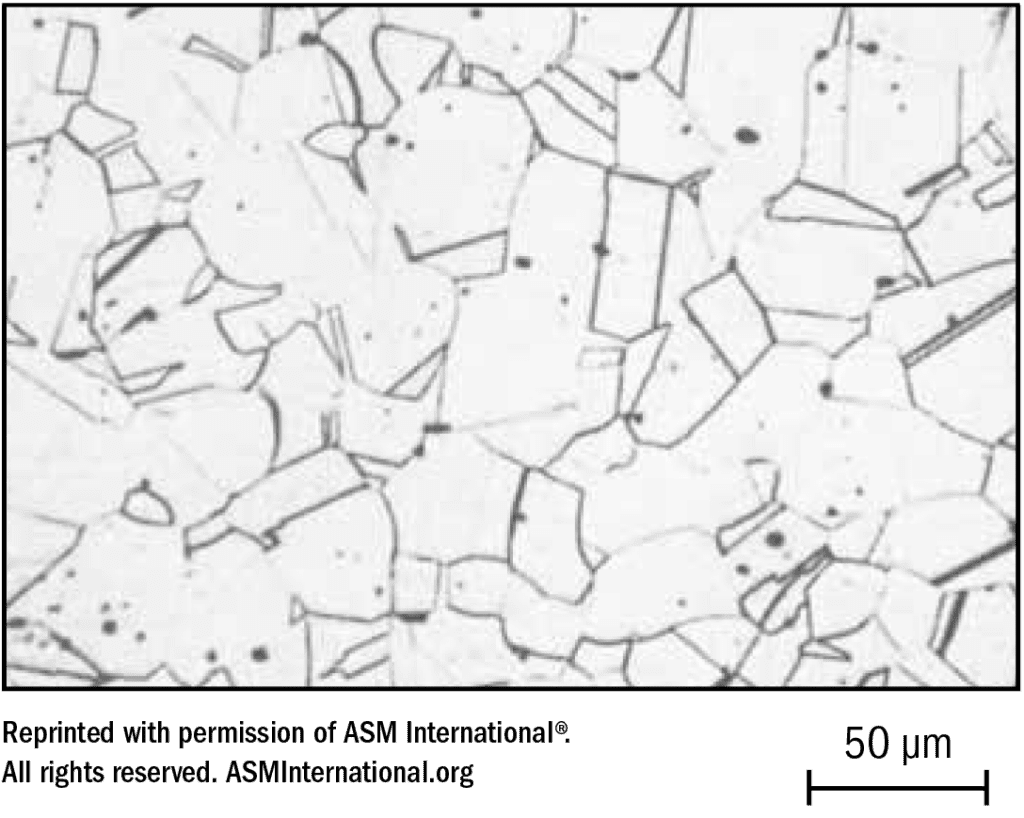

Austenitic Stainless Steel Casting. Austenitic stainless steel castings are non-magnetic. When nickel is added to stainless steel in sufficient amounts the crystal structure

All austenitic grades can be highly durable and corrosion resistant and have high ductility, low yield stress, relatively high tensile strength and good weldability. As such, they have a very

Our high-alloyed austenitic grades achieve their enhanced resistance to corrosion and other properties by heightened levels of chromium, nickel, molybdenum and/or nitrogen, depending on the application at hand. They have good

This category offers a unique combination of high strength and corrosion resistance. These alloys can be strengthened through heat treatment, achieving strengths several times greater than standard austenitic stainless

The austenitic grades 254 SMO. and 4529 are sometimes referred to as 6Mo superaustenitic grades, and 654 SMO as a 7Mo superaustenitic grade. High temperature austenitic grades

This guide provides an overview of stainless steel grades, describes the properties and typical uses of each grade, and compares the different grades.

Austenitic grades A1 A2 and A4 are shown and compared to bar grades 303 304 349S17 316 and 394S17. Mechanical properties for property class 50 70 and 80 austenitic

Popular Grades. Among the most common austenitic stainless steels are grades 304 and 316. Grade 304 typically contains around 18% chromium and 8% nickel, making it an

309 stainless steel is an austenitic stainless steel in the 300 series. Thanks to the high chromium and nickel content, they have outstanding oxidation and corrosion resistance

SAE 316L grade stainless steel, sometimes referred to as A4 stainless steel or marine grade stainless steel, is the second most common austenitic stainless steel after 304/A2 stainless

Austenitic stainless steels generally exhibit good weldability and very good toughness even down to cryogenic temperatures, i.e. they do not display a ductile to brittle transition with decreasing

Austenitic Stainless Steel. Austenitic stainless steels are among the most popular and widely used non-magnetic alloys worldwide. They typically feature chromium and nickel,

There are four main types of stainless steels: Austenitic stainless steels contain a significant amount of chromium, and sufficient nickel or manganese to stabilise the austenite

AISI 316 Stainless Steel (UNS S31600) AISI 316 stainless steel (UNS S31600) is the second most commonly used austenitic stainless steel. Due to the addition of Molybdenum (Mo), SS 316

Austenitic stainless steels belong to a class of stainless steels with a face-centered cubic crystal structure. This structure is achieved using nickel manganese, and

But austenitic grades, like 304 and 316, can become magnetic. This is done through cold work, like bending, pressing, blasting and cutting. Basically, if you buy a rod of 304 stainless, it will likely be non-magnetic. But if you start doing

Austenitic stainless steels do not have high mechanical strength, unlike duplex and martensitic stainless steels. Different grades of this material such as 304, 316, 321, and 347 are more

- Badteppich Beach 60 X 100 Cm Sandbeige

- Steam Workshop::star Trek Adventures Table

- Consultorio Empresarial

- Hochzeit Preise: Was Kostet Die Klavierbegleitung ?

- The Most Recommended End Time Books

- Stand Up Paddling Für Anfänger / Wie Paddelt Man Richtig

- Energiebedarf Der Sonne Weltweit

- Landgericht Aachen: Bankverbindung

- Mithilfe Der Kunst Den Corona-Sorgen Entfliehen

- Verordnung Des Sächsischen Staatsministeriums Der Justiz

- Kirmesmontag, 14. August: Nentershausen Kirmeshochamt

- Hannover 96: Trainer Thomas Doll Mit Wutrede