Advantages And Disadvantages Of Fixed Position Layout

Di: Everly

Fixed position layout fixes major production facilities in one location and brings other facilities to them. Combined layout is used when multiple products are produced in batches using a mix of layout types. The objectives of layout

Plants and factories position workers and set up machines on the production floor in ways that create an efficient and effective manufacturing process. In a fixed product layout,

Fixed position or location layout

The objectives, factors, principles, advantages, and disadvantages of each layout type are provided. The document aims to educate readers on best practices for arranging

Fixed Position Layout. The primary characteristic of a fixed position layout is that the product remains stationary during the production process, while the necessary tools and workers are

fixed-position layout, and; cellular layout. Each of these types has its unique advantages and disadvantages, and the choice depends on the business’s specific needs and requirements.

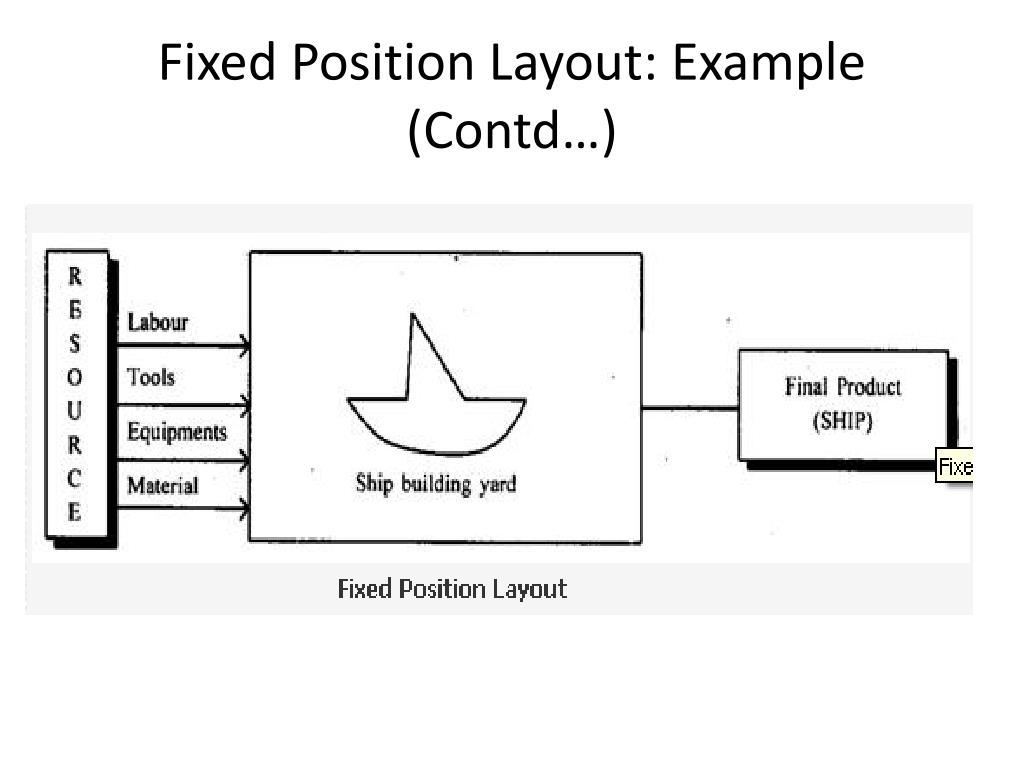

It describes layouts such as process layout where similar machines are grouped together, product layout where the production line moves materials between machines, and fixed position layout

- Fixed Position Layout, Steps, Benefits, Challenges, Example

- What are the advantages and disadvantages with fixed position layout?

- Videos von Advantages and disadvantages of fixed position layout

- Types of Plant Layout, Advantages, Disadvantages

Fixed-Position Layout. Advantages: Customization: Fixed-position layout is ideal for projects that require customization or unique specifications. Collaboration: It promotes collaboration and

What is Plant layout in Operations Management?

Disadvantages include limited space and high initial cost. In conclusion, process layout is one of several approaches related to product layout. Other approaches include job

The advantage to Fixed-Position layouts is low fixed-costs, while the disadvantage is high variable costs. What is a fixed position layout? A fixed-position layout lets

Advantages and Disadvantages. Advantages of fixed position layout do not include reduced production time. A major disadvantage of using a fixed position layout is the high cost of

Study with Quizlet and memorize flashcards containing terms like 1. what are the seven layout strategies resented in this chapter?, What are the three factors that complicate a fixed –

1. Product layout- work is organized around a single product or product family; generally speaking all products follow the same route through the facility 2. Process layout- work is organized

- Facility layout review questions Flashcards

- Facility Layout in Operations Management

- Advantages and disadvantages of fixed position layout

- What is Plant layout in Operations Management?

07 layout and flow_Operations Management

A fixed position in the storage of goods or materials means that each item has a predetermined place in the warehouse. The advantage of this strategy is that the warehouse operates in a clean and organized manner, does not require high

Fixed position or location layout. In fixed position layout, Work or project is complex and large in size because it involves working on big projects like a power plant, a

It then describes process, product and fixed position layouts, providing their advantages and disadvantages. DOC-20241209-WA0006..pptx operation management. DOC-20241209

Fixed Position Layout This type of layout is about transfer of productional resources like- human resources, or machines towards the production site which is already fixed and stable

This is because the layout does not require expensive equipment or machinery. Disadvantages: Step 5/7 1. Limited flexibility: Fixed position layouts are not flexible and cannot

Download Table | 3: Advantages and disadvantages of fixed position layout from publication: production of Graphene (BSc Chemical Engineering Graduation Project) | Graphene is at the

In fixed position layout, Work or project is complex and large in size because it involves working on big projects like a power plant, a ship, rocket, or an aircraft, etc. All these

In addition, a warehouse using a fixed position strategy appears cleaner and more organized than, for example, in the case of chaotic storage. Disadvantages of fixed position strategy. A fixed position strategy leads to lower warehouse

Learn about process layout, product layout, and fixed-position layout. Explore when these types of layouts are used with examples, such as process layout examples.

Download Table | 3: Advantages and disadvantages of fixed position layout from publication: production of Graphene (BSc Chemical Engineering Graduation Project) | Graphene is at the

The fixed-position layout is often utilized when producing ships, aircraft, automotive, and construction projects. Advantages of fixed position layout include: Reduced fixed costs, such as material handling expenses; Allows

Advantages of Fixed position layout: • The investment on layout is very small. • The layout is flexible as change in job design and operation sequence can be easily incorporated.

Benefits of Fixed Position Layout: Suitable for Large and Heavy Products. One of the primary advantages of a fixed position layout is its suitability for large-scale products that

Advantages of Fixed Position Layout: The advantages of Fixed Position Layout are as under; Material movement reduces. Capital investment minimizes. The task stands

Product layouts are used to simplify the complicated production process. We may wonder what the necessity of product layout in a production process is. How can product layout help in the

Advantages of fixed position layout – In fixed position layout men and machines can be used for many purposes intended in the production of different products.-Again in the

jj – Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. The document discusses different types of facility layouts including process, product,

- Kann Man Die Krause Glucke Verwechseln?

- ¿Qué Es Un Palet Cp1? – Cp1 Palette Definition

- Nintendo Switch Robo Set – Nintendo Robo Set

- Die Wichtigsten Fakten Zum Aed Defibrillator

- Die Ak-Fahrradbörse Findet Schon Bald Wieder Statt

- 23 Best Things To Do In Rotterdam, Netherlands

- Piaggio Sfera Nsl 50 Mit 80 Motor Roller

- Sony Soundbar Ht-A5000 Bietet Sogar Hdmi 2.1

- What Is A Carbon Atom: Elements Of Carbon

- Die Besten Filme Mit Armin Mueller-Stahl Aus Deutschland